Quick Links:

Zen

and Art Home Disclaimer

Errata

Parts and Parts

Vendors

Truck Sales Service

and Repairs

Engine Fuel Hydraulics Radiator and Cooling

Air System Brakes Wheels Tires Electrical

and Batteries

Transmission Clutch

Axles Hubs Body Air

Conditioning

Tools

Safety

Radiator and Cooling

Our trip to Alaska revealed that there were some pretty important maintenance and repair actions that needed to be accomplished to keep the rig running in top-notch form. We had experienced a few issues that had to be addressed, and since I was "in the mood", we decided to perform some upgrades that would increase our enjoyment of the truck on future expeditions.

The photos below are what we saw.

Because the radiator on the 1300 (and all SBUs in general) are offset, there is a somewhat hokey system of belts and pulleys that deliver engine power to the fan. The first belt goes from the crankshaft to a transfer pulley that is attached to the corner of the radiator. That pulley is hooked to a shaft and bearing set that transfers motion to another pulley that is hooked to the actual fan via a second belt. The fan pulley, and its associated bearings have never been serviced during the 15 years that I have owned the truck and the whole system was a tad noisy, so I decided to replace the entire thing. So, we started at the water pump and replaced it as well as the thermostat and all the hoses. Then, we pulled the radiator and the entire transfer pulley system. The entire setup was a press-fit and during my somewhat ham-handed dis-assembly, I broke the fan pulley.

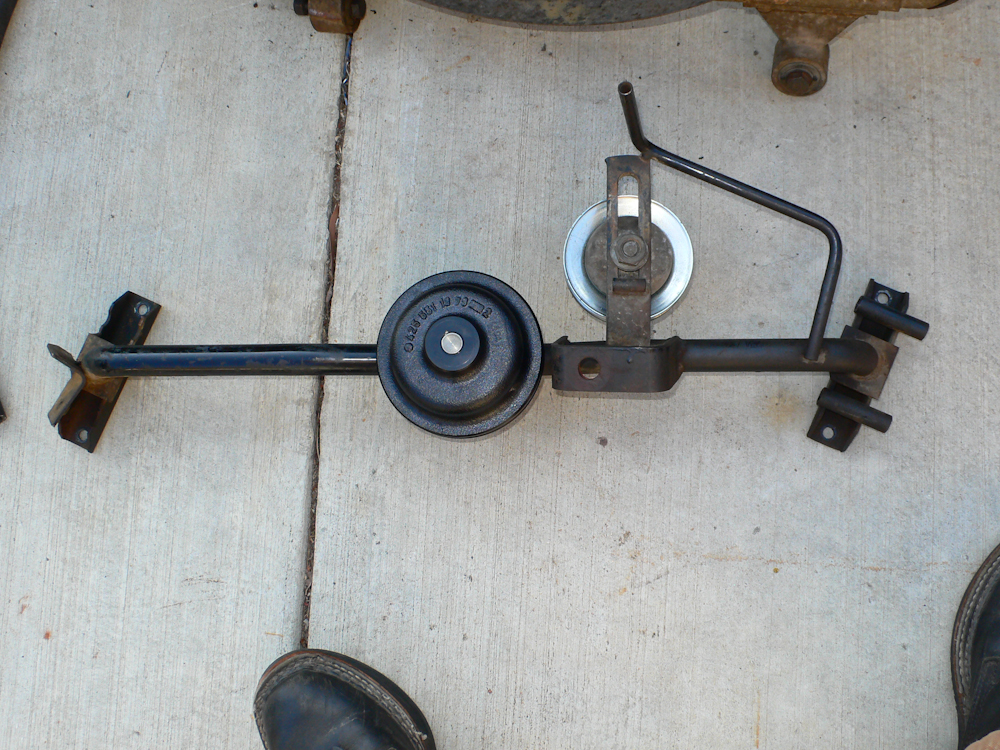

The fan pulley attached to the back end of this assembly and the fan blades bolted onto the front face. There is a bearing pack that is pressed into that frame that I could not get out using a conventional attack, so I asked Kai to use his multi-ton hydraulic press on it and it did come out, albeit with substantial difficulty.

This is the transfer pulley after I replaced both bearing packs in it and replaced the idler pulley (on the arm) This was a bit tricky, but we did complete the bearing swap without outside help.

This is the new bearing pack that was installed in the fan pulley frame. This is a big bearing set and was quite pricey (as are most mog parts).

The radiator was last serviced in 1996 or so. It was time to do it again as it had developed a leak in northern Yukon, but we were able to stop it with some Alumaseal radiator sealant. The sealant worked well and did not seem to cause side effects. The radiator was re-cored, resoldered and pressure tested. The price was about $600; less than 1/2 the cost of a new one. During the reassembly of the radiator, I discovered a big crack in the fan cowling that would need a splint. More on that later.

Removal of all the plumbing from the front of the engine compartment left a big, gaping hole in the front of the truck. I attempted to service a few other components while the thing was apart and succeed at several, but it was not a clean sweep. Note that the water pump is removed in the photo above.

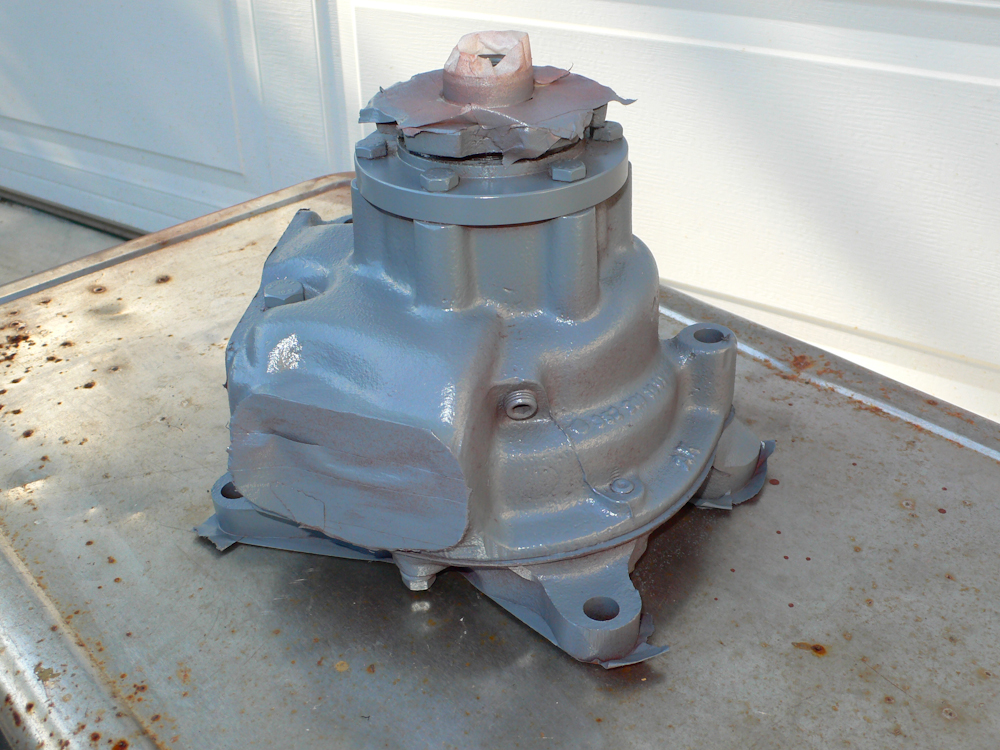

I primed a painted the new water pump before installation.

As I was preparing to reassemble the radiator and cowling, I discovered a big stress crack at the junction of the cowling and the transfer pulley. Note the crack to the right of the right bolt hole in the photo above. This was going to require some careful welding, so I solicited the help of Mark Mitchell and his TIG welder. The photo above shows the splint that will be added into the trough behind the bolts. Note that the square tubing has been milled out to provide clearance for the existing transfer pulley attachment bolts.

The splint is in place, but not yet welded. Note the crack is right next to where the transfer pulley attaches.

The crack is quite long and would have likely resulted in a full fan and radiator failure. Given my luck, it would have happened someplace very inconvenient, so I am glad that I saw it before it fully failed.

The fan pulley support assembly with new pulley, bearings and a new idler pulley. This assembly hooks to the back of the fan cowling and the 2 bosses on the right bolt onto the transfer pulley assembly. The balance of the actions on the radiator were time consuming and inconvenient, but were completed successfully without incident.

Quick Links:

Zen

and Art Home Disclaimer

Errata Parts and Parts

Vendors

Truck Sales Service

and Repairs

Engine Fuel Hydraulics Radiator and Cooling

Air System Brakes Wheels Tires Electrical

and Batteries