The

photos below are what we saw.

First

action was completion of the intercooler mount modifications to

a degree that we could judge the clearance with Lance. The

partially completed mount was inserted into the frame sockets

and Thor was backed underneath the lift.

The

partially completed intercooler frame (harvested from the old

headboard) was inserted in the sockets on the upper frame rails.

Axle

retaining bolts were removed in preparation for insertion of

sub-frame components.

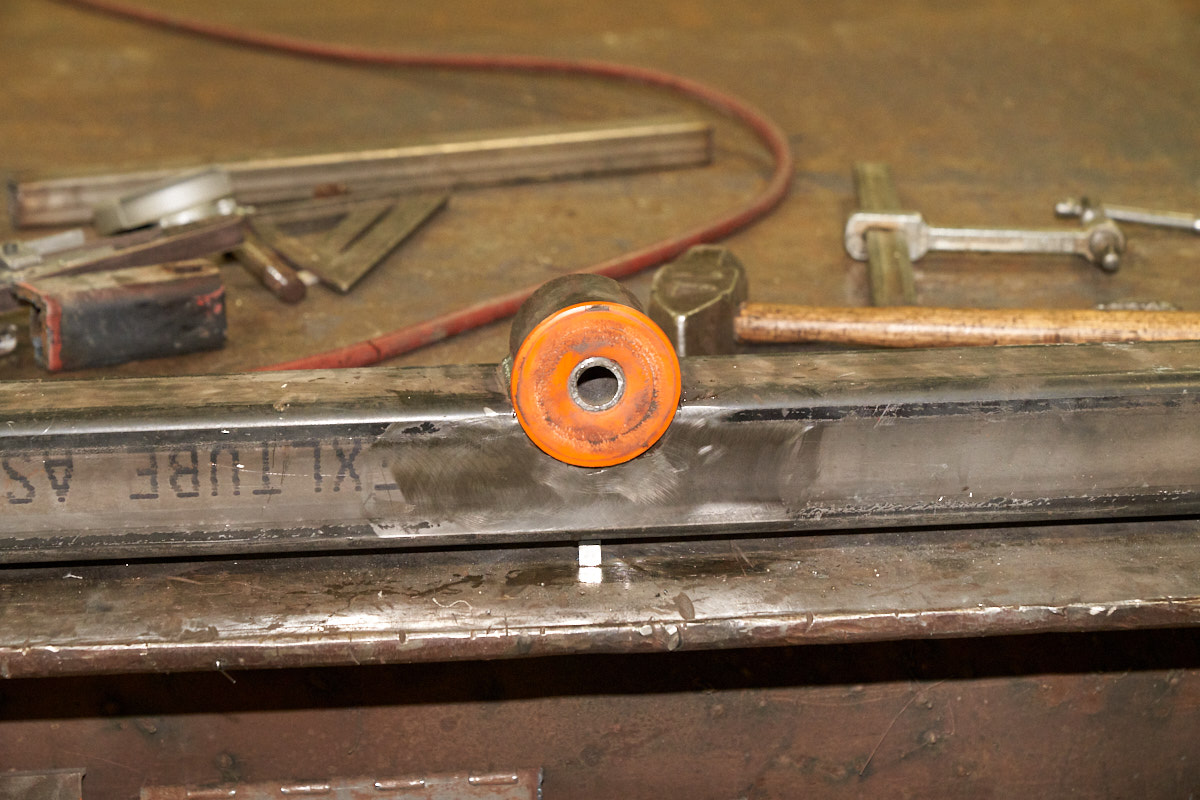

The

bushing was put in the lathe and material was removed until it

fit within the designated pipe.

Polyurethane

is a fickle material and can only be removed in small cuts or

the material will gouge so patience, and multiple cutting passes

were needed.

Soon the

bushing was small enough to fit in the pipe.

A

semicircular hole was cut in the 3x3 tube and the pipe was to be

welded in the pocket.

The

finished part ready for a test fit.

The

bushing was a snug fit in the pipe and the mounting pivot.

The 3x3

tube was cut short to allow direct connection to the old hitch

yoke. Caps will be welded on both ends of the tube and

they will have angle attached to support the outside frame

rails.

Next up

is the rear sub-frame member. We chose 2x4 rectangular

tube since the rear mounts will be on spring bolts.

2x2 tube

was placed between the axle mounts to assist in spreading the

load of the mount on the frame rails. The spring bolt

mounts were moved aft and we co-opted one of the bolts from the

frame cross member. Tomorrow, the other part of the spring

bolt mount will be fabricated and attached.

We had

to place our propane bottle on a chair as a temporary measure

until our final propane tank arrives (hopefully tomorrow) and

plumbing is addressed. The new tank will mount between the

frame rails and will have a remote full/bleed connection.

The full

weight of Lance is sitting on Thor's frame, albeit not yet

welded. But, the arrangement was sufficiently stable to

allow us to sleep in Lance overnight. Note the step ladder

which was required because our folding stair bracket was not yet

attached.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2019, all rights

reserved.

For your enjoyment only, not for commercial use.