A lot

of planning and test fitting was required before final mounting

locations were chosen for the inverter and solar support

equipment. Cable routing needed careful consideration as

many of the routes were difficult to access or required removing

appliances to gain access to the cable route.

The photos below are what we saw.

We

needed to access both the refrigerator compartment and the

heater compartment directly below to route our cables. We

used Ancor marine safety cable for both AC and DC wiring.

This wire is expensive, but the best available.

We

needed to mount two meters on the wall. To the left is the

remote control terminal for the inverter. On the right is

a Blue Sea Systems "State of Charge" digital panel meter.

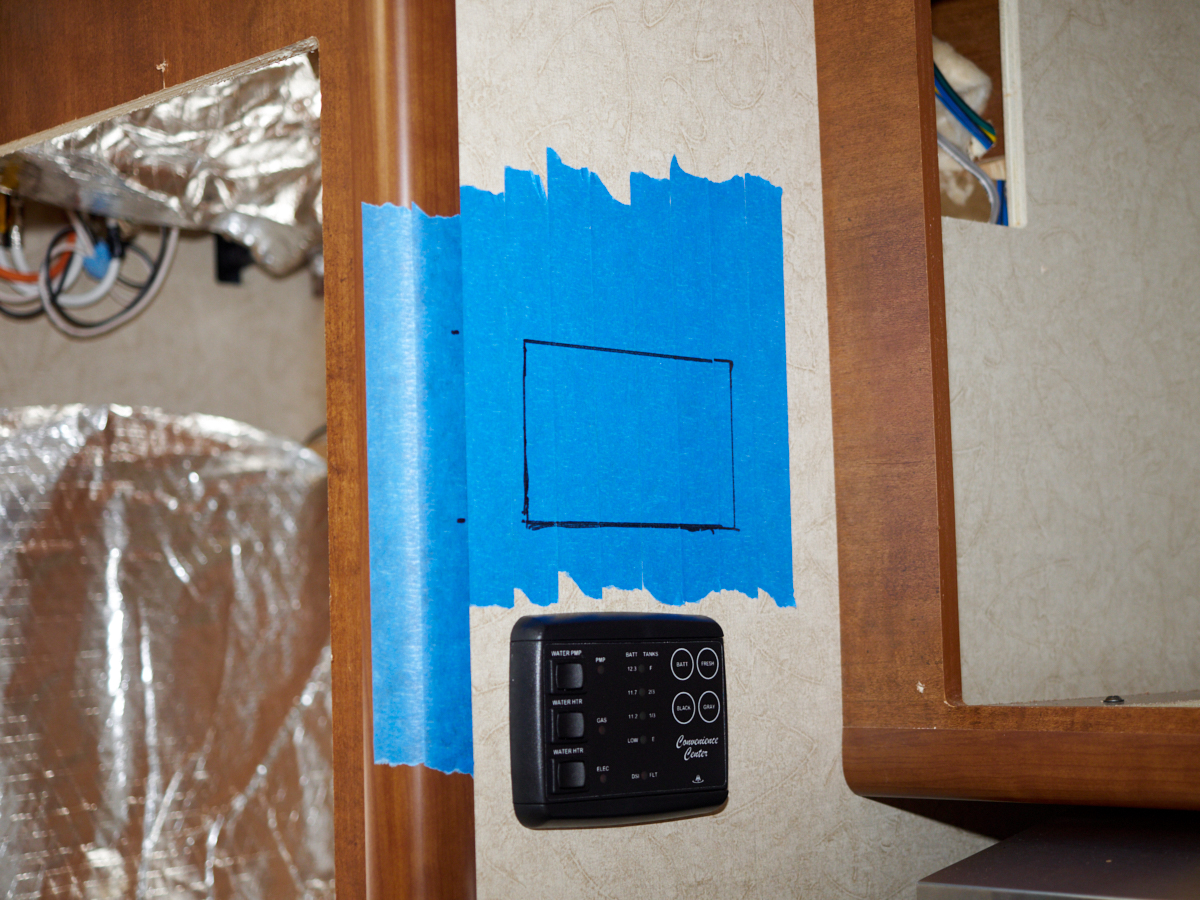

The

inverter remote control was the bigger of the two and was

installed first. 3M blue tape was applied to provide some

protection from tool marks.

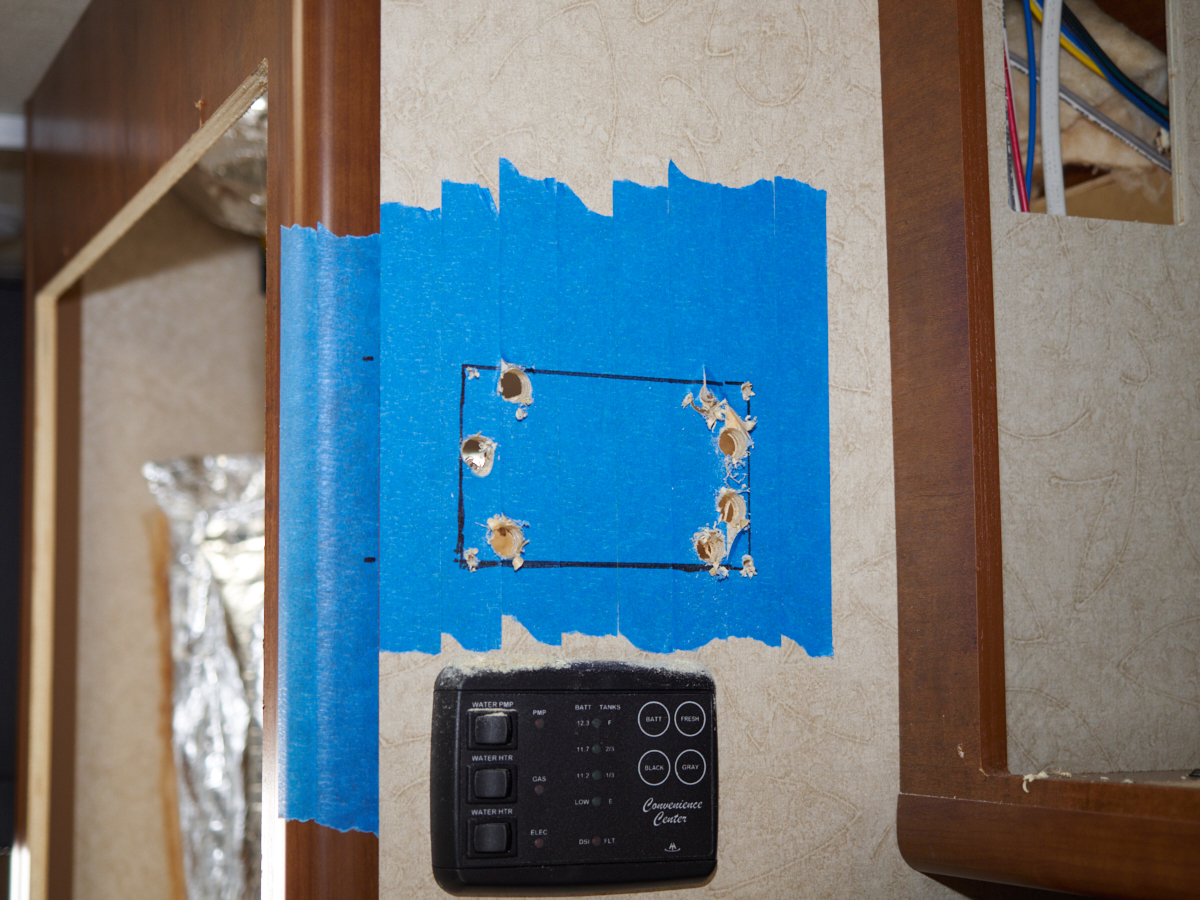

Holes

that were big enough to pass the saw blade were drilled in the

10mm plywood walls. The jig saw was inserted and cuts were

made to remove the balance of the material.

The

State of Charge meter was installed with a simple 2" hole

saw. Note the size of the existing wire bundles.

A

twisted pair harness was prepared and combined with some power

feed lines to supply the small meter.

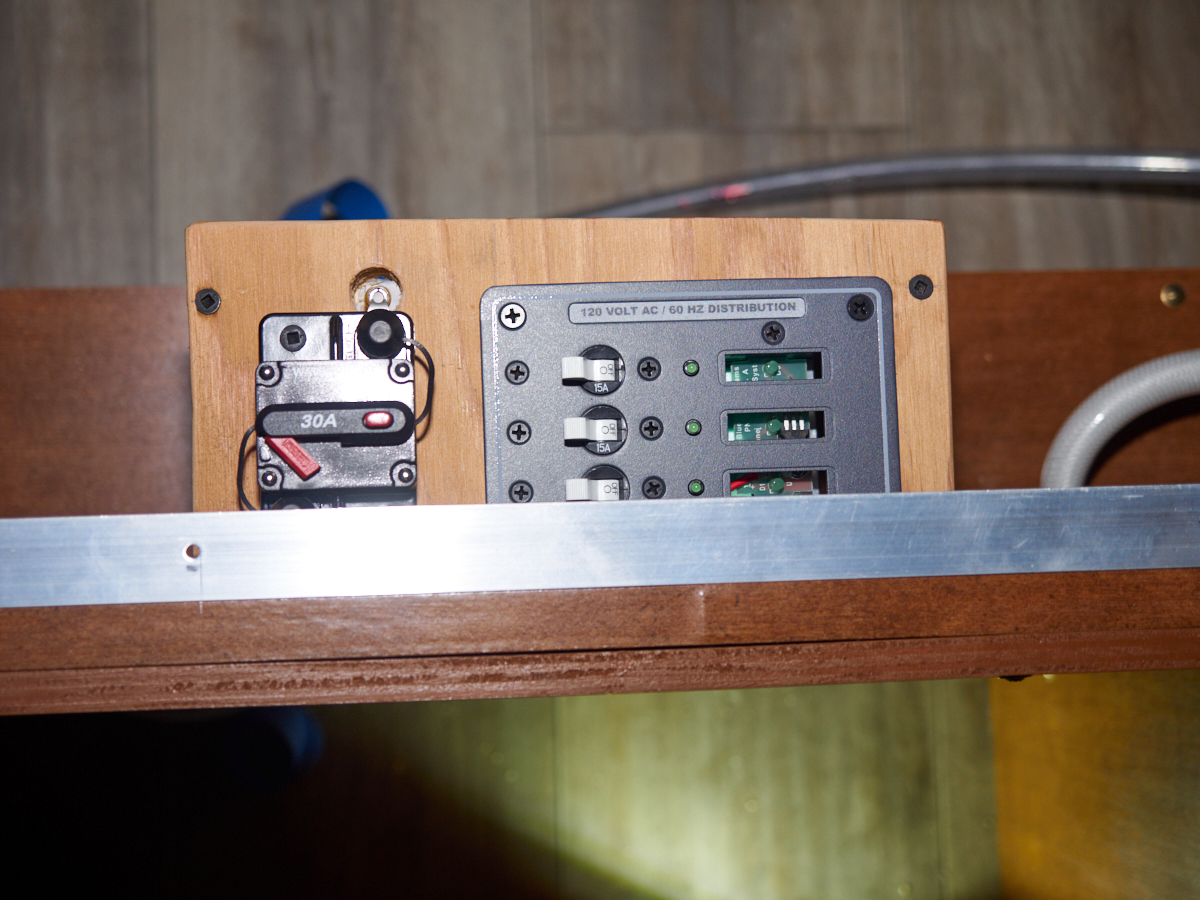

The AC

subpanel and solar circuit breaker were attached to the wall.

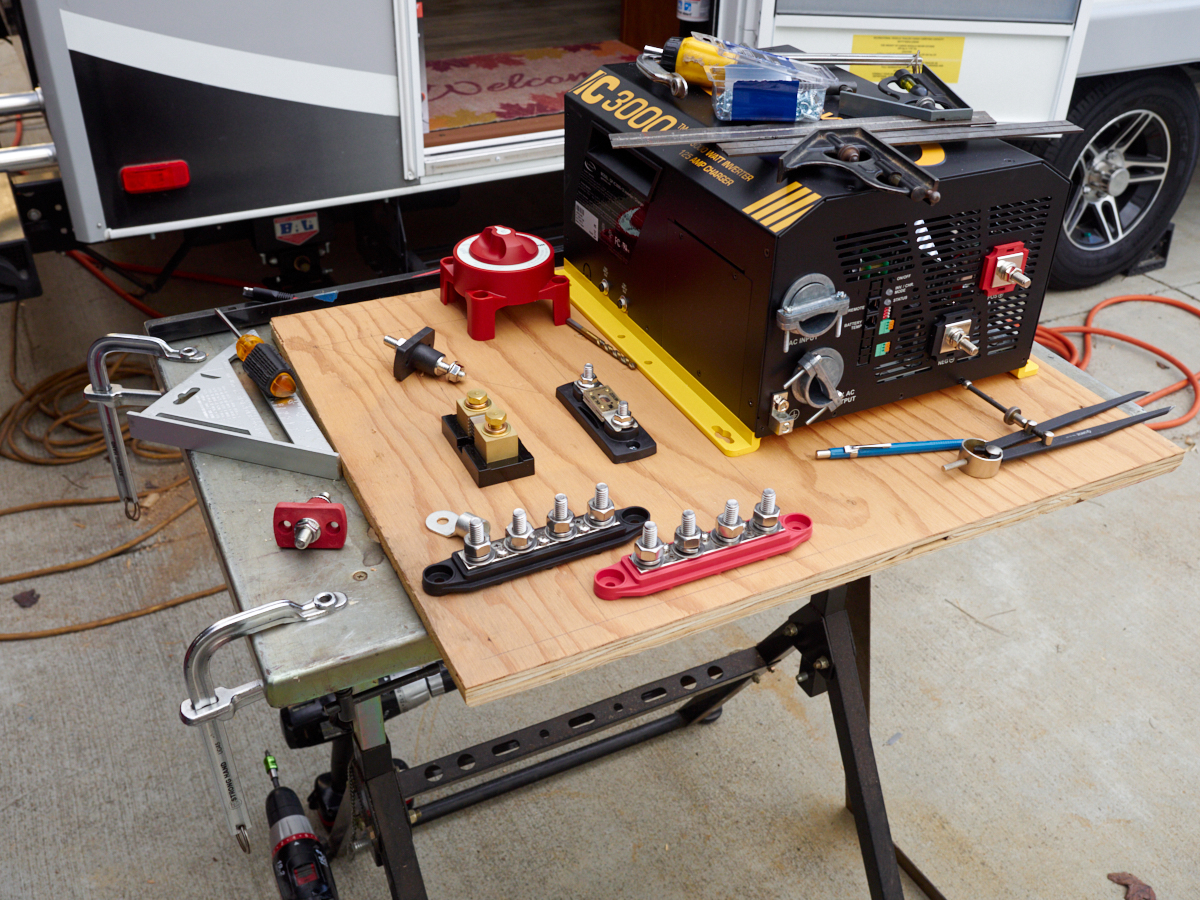

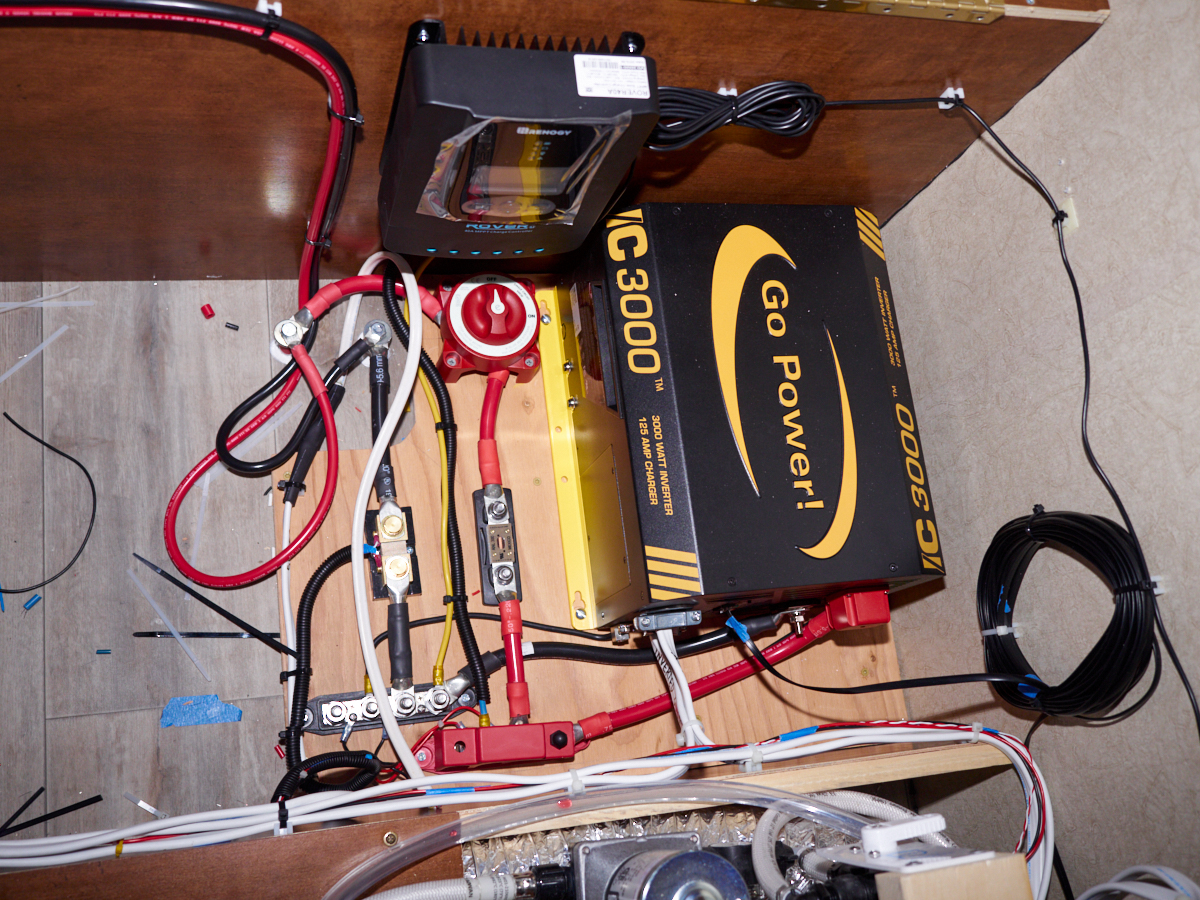

The

below-the-bed cubby was measured and a plywood mount for the

inverter and high-current DC lines was prepared. The

components were arranged on the mounting board to test the

layout.

Components

were attached to the mounting board and connecting cables were

cut and fabricated.

Meanwhile,

the inside of the camper was turning into a cesspool of tools

and zip-tie clippings.

The

solar charge controller was mounted on the forward wall of the cargo

compartment and the cables were dressed and attached using

screw-type zip-tie mounts. The #4 AWG cables were

repositioned for circuit testing. During normal operation,

they will be attached to the DC buss bars at the bottom of the

photo above.

Once the

installation and preliminary wiring was completed, we attacked

the solar installation. Panels were recovered from their

installation on the HiLo and moved to the Lance. The Lance

came from the factory pre-wired for solar including a

through-roof mounting setup. I had to acquire MC4 cable

connectors (Amazon) and then attached these connectors to the

wires from the panels. I also purchased Y connectors that

allow parallel connections of multiple panels.

Once the

panels were installed and the circuit turned-on we were able to

verify the operation of the SOC meter and the polarity of the

current-sensing shunt.

My buddy

Vince came through town and he helped us affix the panels to the

roof of Lance. We used 1/4" pop rivets and 3M 5200 marine

adhesive for the installation. Note the white blobs on the

roof. We applied a generous coating of the 5200 adhesive

to insure that there were no leaks in the cover membrane.

Visible

in the photo above is the second solar panel, Fantastic fan and

digital TV antenna.

We were

pleased with the final installation.

Next up

is the installation of the entertainment system. For

Lance, as with the HiLo, the system consists of a Mac Mini, a

large hard drive with video files, an Apple TV and some support

circuits including an A-B HDMI switch and an HDMI audio extractor.

The

entertainment system hardware will be mounted on a shelf

installed in the cabinets. Holes were drilled in the

cabinet walls to allow passage of the HDMI cable that supplies

the display panel. Mounting supports for the shelf were

cut and test-fit into the cabinet.

Most of

the entertainment equipment is powered by "wall warts" (small

transformers that plug into a socket). These wall warts

use up more than their fair share of plug real estate thus

requiring a large socket bar to support our installation.

The plan

is to put our WiFi router on one of the cabinet walls, so a test

fit was required to confirm feasibility.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2019, all rights

reserved.

For your enjoyment only, not for commercial use.