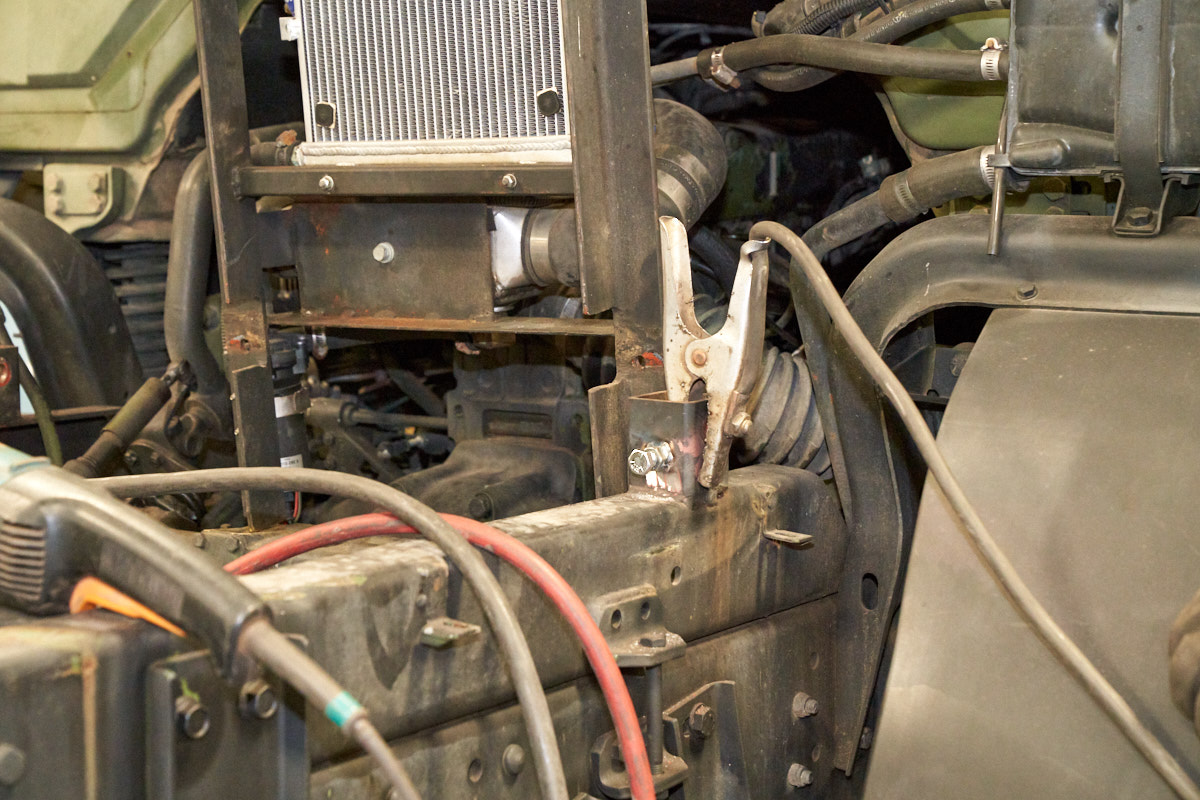

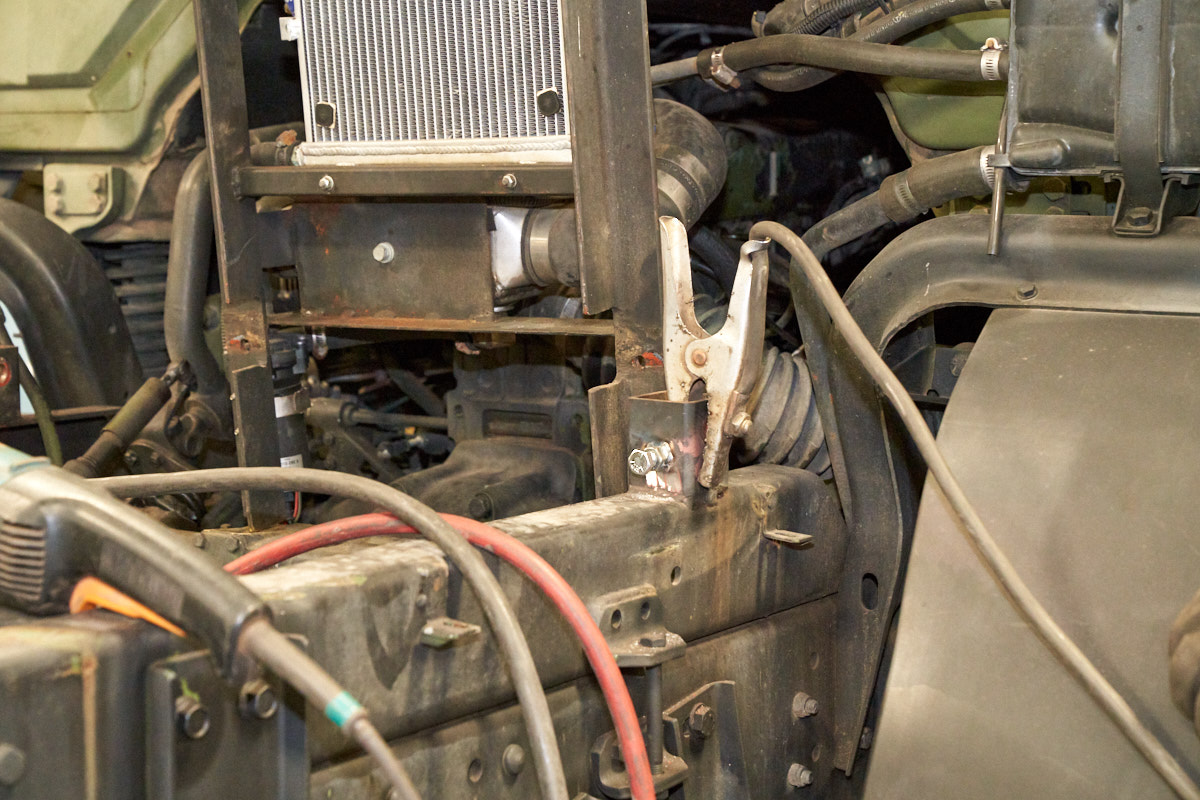

The photos below are what we saw.

The

final action on the intercooler mount was the installation of

nut/bolt clamps to prevent movement once the mount is installed.

Once the

final material for the propane mount was available, another

test-fit was performed to insure that things are good.

Thor

came equipped with an "armstrong" (AKA manually operated) tire

crane mounted between the rear frame rails. The crane is a

worm-drive design that prevents the cable from unwinding

unintentionally. Given that the crane was 30 years old, it

was removed from the frame, the rope was unwound and the unit

was put in the solvent tank. We then inspected it and

determined that the difficulty in operation was due to a plate

that had bent (likely due to load). Note the tack welds at

the right side of the crane. The plate was bent back, a

brace was added and welded to prevent another failure.

The plan

is to cut the actuation shaft and replace it with an old socket

that will allow use of a normal ratchet or impact wrench to

operate the crane. The worm gear is clearly visible in the

photo above.

The

intercooler mount, sub-frame cross members and the propane mount

await their turn in the paint booth.

The used

socket was put into the lathe and the cracked portion was

machined off.

The

center was then drilled to allow easy mating with the existing

collar.

The

collar was welded to the socket.

The

refurbished crane with cleaned synthetic cable and socket ready

for installation.

Finished

crane attached to the rear frame cross member.

A final

design for the battery box and lifting mechanism was presented,

material was cut and welded.

A test

of the crane with the actual batteries. It lifted "easily"

but the synthetic cable stretched more than we wanted.

Since we did not know the provenance of the cable, we elected to

replace the synthetic with stainless steel cable.

The

support frame was added to the battery box.

'

'Another

test fit was performed using the essentially completed

box. The driver was used to lift and lower the box.

We have

elected to replace the synthetic rope with stainless steel

cable.

The

frame mounting tabs were cut from 3/8" strip. The tabs

were heated with a torch and bent 45 degrees to better match the

junction with the lower frame rail.

The

battery box is essentially complete lacking only the power post

attachments and the actual battery restraining straps.

Meanwhile,

the outside paint booth was used to spray the fabricated

components. Satin black is the color of choice.

A rather

fuzzy photo, but the final geometry of the box is clear from the

photo above.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2019, all rights

reserved.

For your enjoyment only, not for commercial use.