The photos below are what we

saw.

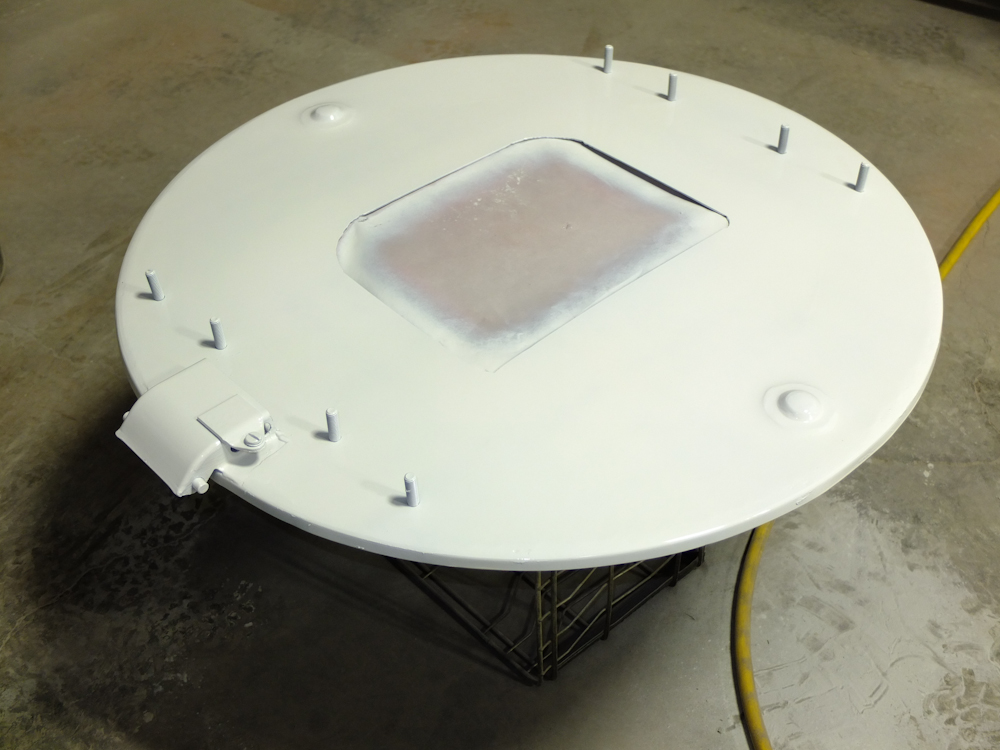

The cutting of the cover

plate for the hatch was completed.

Next the mounting studs for

the actual a/c unit were added. The large holes in the

plate are to accommodate the hatch locks.

Rob elected to braze the

edges both to protect from warping and due to the thin metal

thickness.

The completed brazing job

took about an hour and when it was done the heat of the torch

fried the paint close to the joint. Above, the hatch

before it was cleaned up for new paint and primer.

When the hatch was completed

and painted, we moved on to completing the mounting for

the compressor. Rob took a 1"x1" length of square tube and

welded on a 3/8" ear for the tightening bolt.

Two small tits were welded

onto the front and back of the hatch to cover the latch

mechanisms. The whole hatch was smoothed out with some

body filler, sanded, primed and painted.

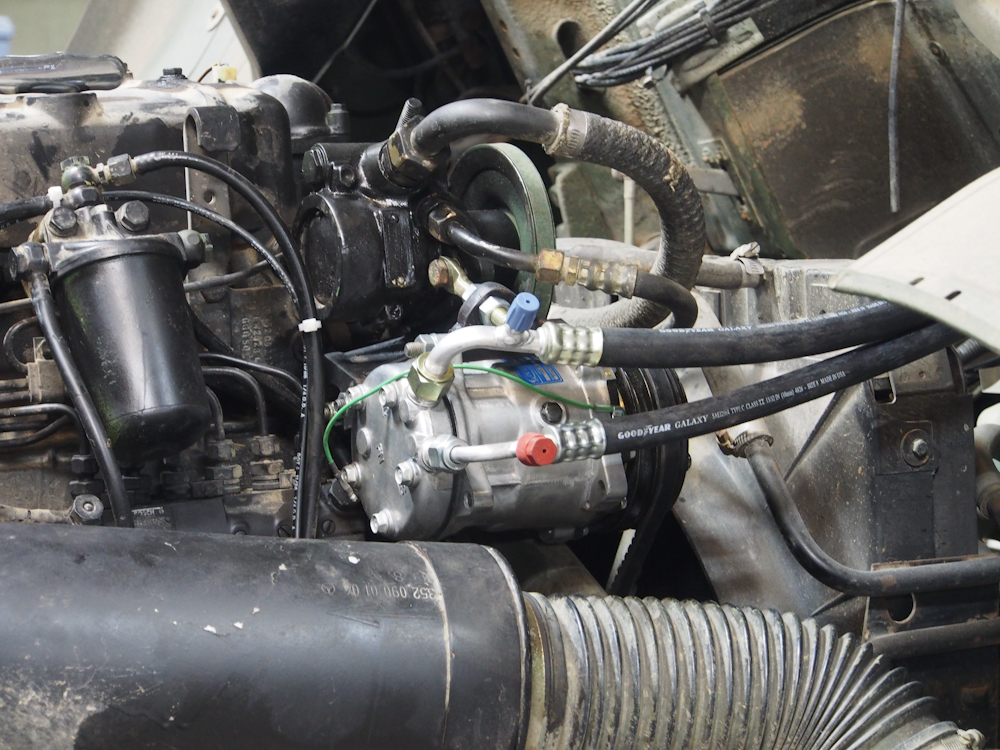

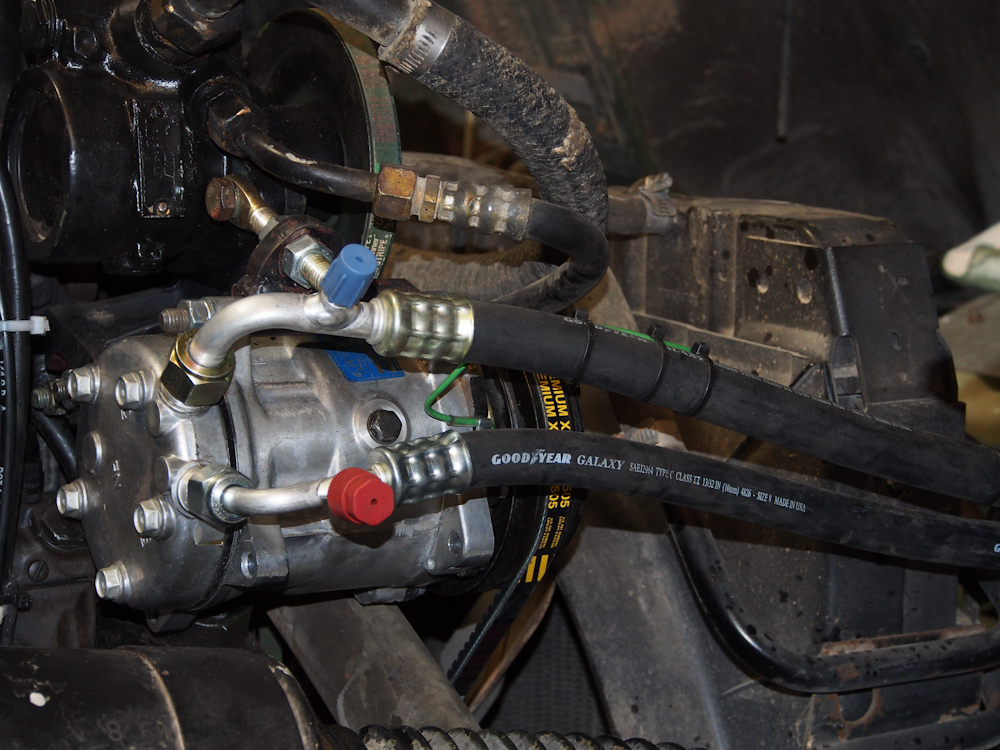

The compressor is now fully

installed with the compressor end of the hoses attached..

The hoses were routed under

the cab and up the back wall.

The hoses were draped over

the cab as the required lengths were determined for each hose.

The hatch was test-fit to

the a/c unit prior to fully bolting the hatch to the unit.

The hoses were routed along

side of the cargo bubble on Thor's cab. Nutserts were

installed through the sheet metal of the cab to allow use of

bolts.

Nuts and lock washers were

added to the studs to attach the roof unit to the hatch.

We added the control panel

to see what it would look like when it is installed.

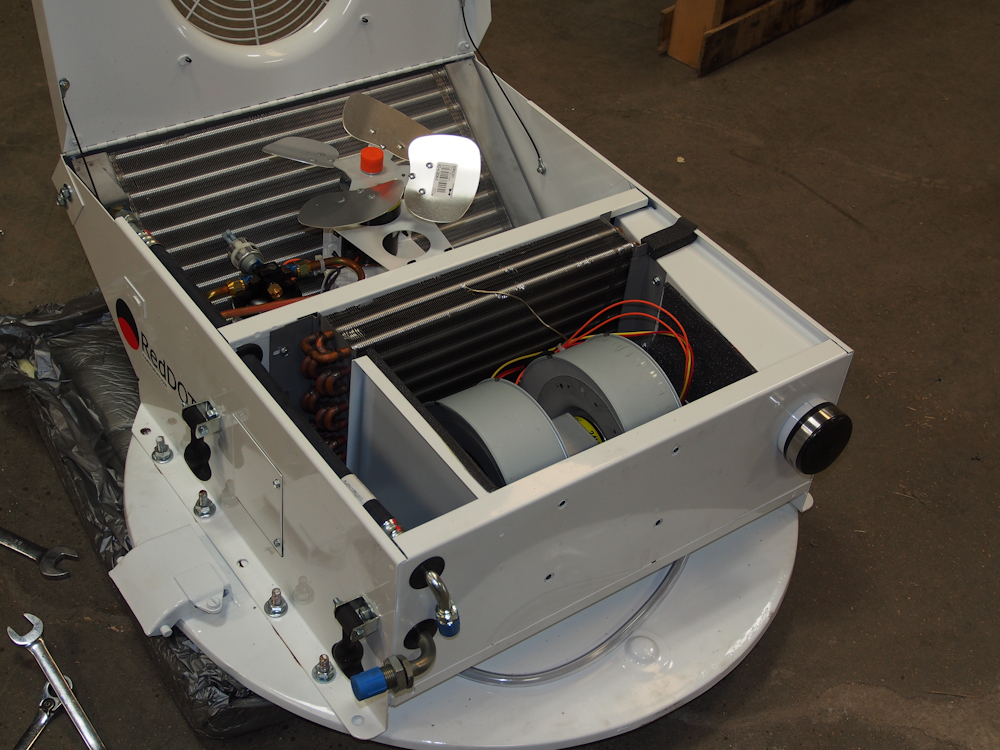

We examined the insides of

the roof unit to determine what needed to be done to rotate the

hose fittings to the correct angle for the compressor lines.

The roof unit was picked up

with the fork lift.

The fork lift made easy work

of lifting the 100+ pound unit to the roof.

The unit was placed right on

the hatch opening.

From the inside, things look

good. The photo above shows the hatch before the control

cover and modesty panel were installed.

The hose ends were crimped

on and the fittings adjusted to the correct geometry.

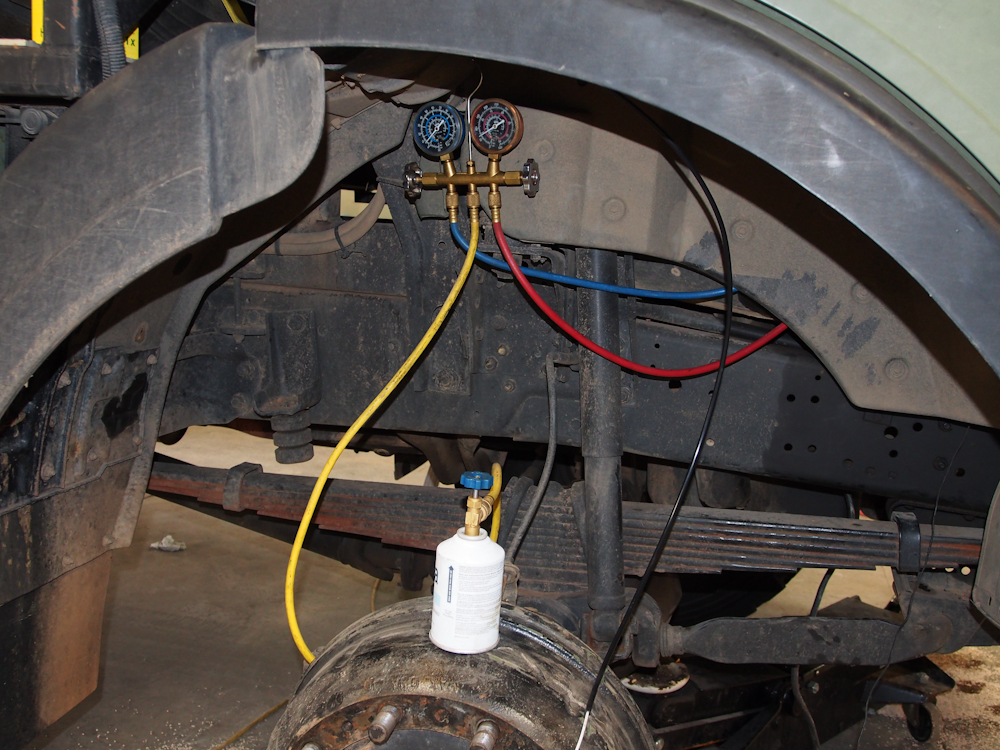

Rob got his vacuum pump out

to evacuate the air from the compressor system and check for

leaks. No leaks were found.

Due to the size of the

system and the length of hose, many bottles of refrigerant were

added.

Once the system was fully

charged and checked for correct output temperature, the control

wiring harness was installed and cinched up with tie-wraps.

Several fuel delivery lines

had to be moved as part of the installation and some were in

danger of abrasion damage due to the vibration of the

engine. So, rubber hose was strategically placed to

prevent damage. An ounce of prevention is worth a pound of

cure, or so they say. I am guessing in the metric world

they would say "a gram of prevention is worth a kilogram of

cure".

Thor was locked down and all

the cab electrical connections were re-installed. The oil

and filter were changed and the front differential oil was

flushed and refilled.

| Previous Adventure | ||

Photos and Text

Copyright Bill Caid 2012, all rights reserved.

For your enjoyment only, not for commercial use.