We left

NWOR and returned to Wenatchee and stayed at the Confluence

State Park to do laundry and other associated chores. From

Wenatchee we headed south along the Columbia River toward Richland,

WA to visit my friends Mike and Rachel. Mike, having

worked at the Hanford Nuclear Reservation (previously called the

Hanford Engineering Works) arranged a tour of the historic "B

Reactor".

The photos below are what we saw.

We

passed yet another dam on the Columbia River. This one is

the Rock Island Dam downriver from Wenatchee.

Further

south, we came upon a viewpoint that gave us a nice view of the

Columbia River gorge.

Another

low dam on the Columbia River near Desert Air, WA.

We met

our friends Mike and Rachel in Richland, WA. They took us

on a walk around the neighborhood and we came upon this

sign. General Leslie Groves was the "father" of the

Manhattan Project that created the atomic bomb. Richland

is the town where the plutonium for the bomb was created.

Richland was chosen for a variety of reasons including access to

plenty of cool water (Columbia River); sparse population; easy

access to electricity (Grand Coulee Dam); and access to gravel

and aggregates for the large amount of concrete that was needed

to construct the facilities.

The park

was really nice, right along the banks of the Columbia

River. While walking, I spotted this fellow having fun

doing doughnuts on his jet ski.

Mike is

a fraternity buddy from Colorado School of Mines and having

worked at the Hanford Reservation offered to get us on a tour of

the "B Reactor" at Hanford. Our response was "hell

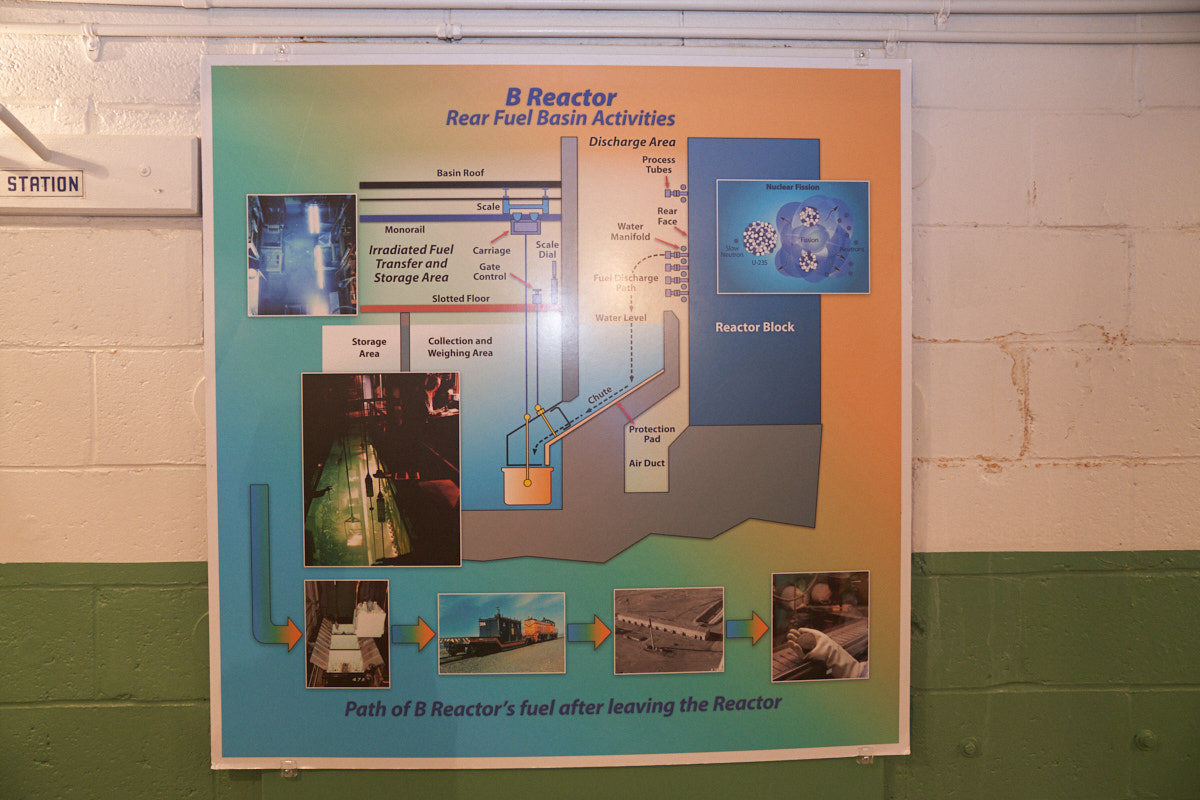

yes!" This reactor created the first usable amounts of

plutonium that later become the core of the Nagasaki bomb.

The reactor was taken out of service long ago and has been

cleaned up to allow visitors to tour the facility. The

building is very unassuming and plain but it was built in only

11 months and then used from 1944 to 1968.

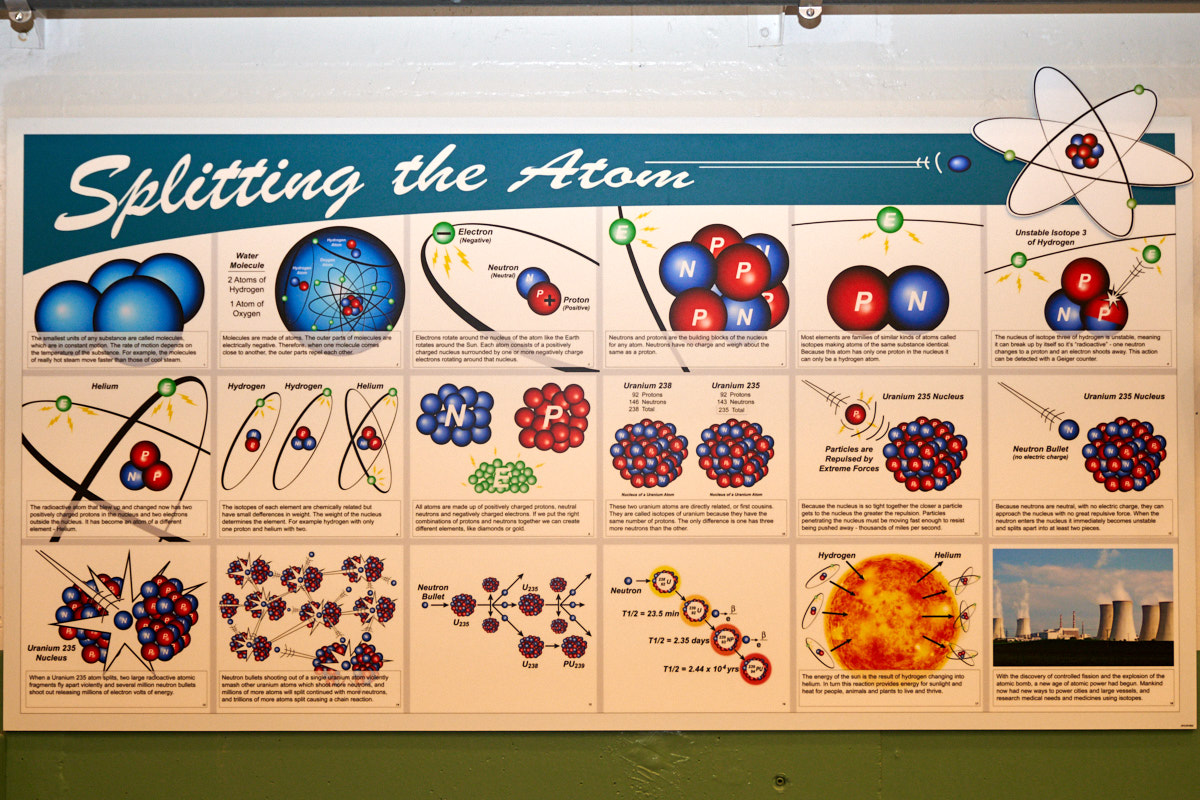

There

were a number of nice displays in the entry area of the

reactor. The chart above depicts the process of fission.

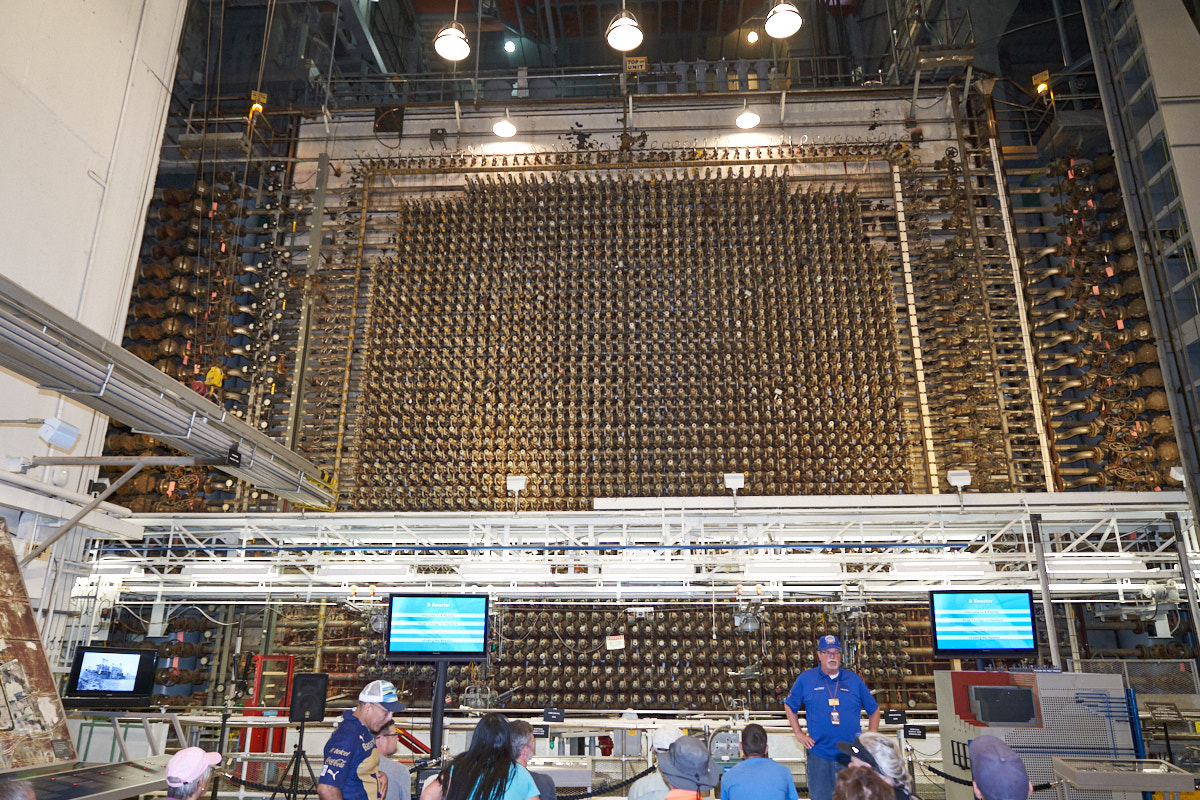

The tour

started at the front face of the reactor. The fellow in

the blue shirt is the docent for the tour and one of Mike's work

mates. Designed by Enrico Fermi, this reactor is a graphite-moderated

design that uses water cooling.

The face

of the reactor was a huge matrix of caps, plumbing and

valves. Each of the items above are the end caps to the

so-called "process tubes" that contained both the atomic fuel

(mildly enriched U-235) and the raw material for breeding

plutonium (naturally occurring U-238). Fuel and spacers

were loaded into each tube and then the tube caps were installed

to allow cooling water to be pumped through the tubes to keep

the reactor from melting down.

At the

side of the reactor face was a huge pipe manifold that carried

the cooling water to the process tubes. The labels on the

pipes were used to locate individual process tubes.

This

display showed the various kinds of spacers used in the process

tubes.

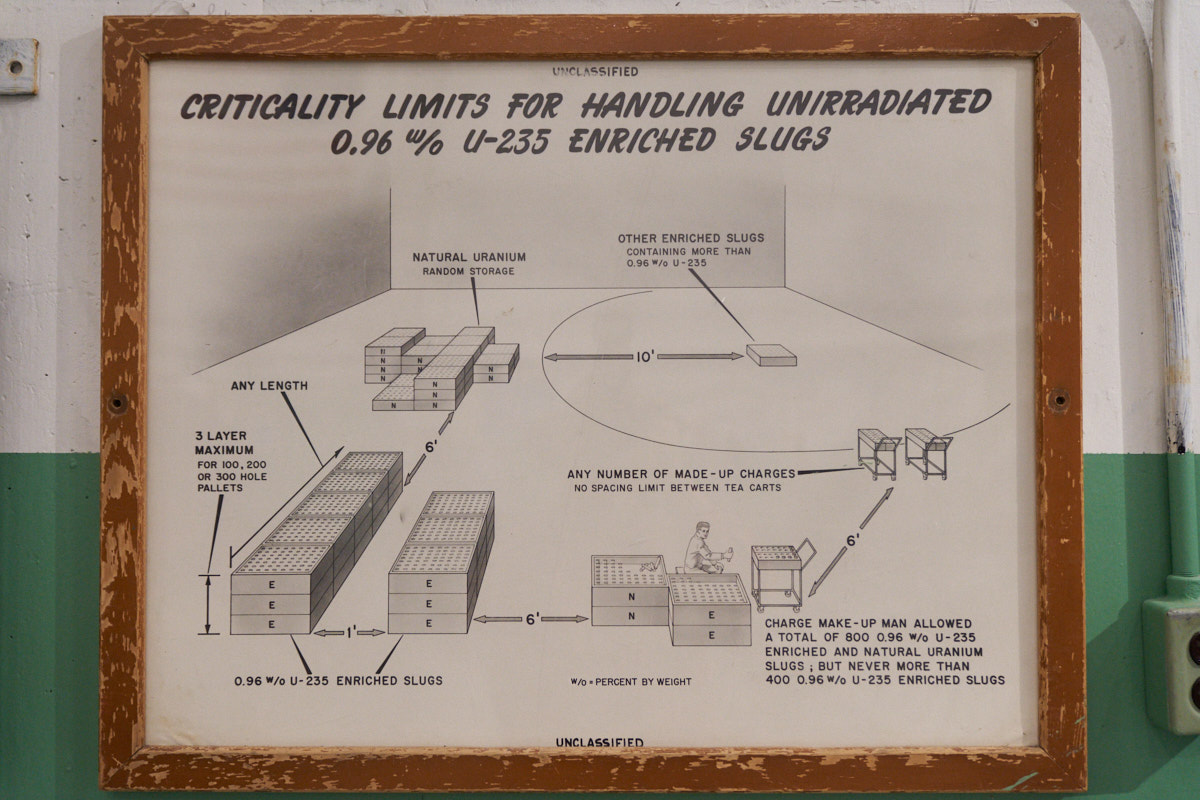

The fuel

was contained in aluminum "slugs" and consisted of natural

uranium or enhanced uranium.

Working

with enriched uranium presented many risks and one issue that

could not be ignored was the physical geometry of

"criticality" Stated simply, it was possible to arrange

the fuel in a pattern that would cause the material to start

reacting outside of the reactor. If this happened, the

results would be catastrophic and fatal for anyone nearby.

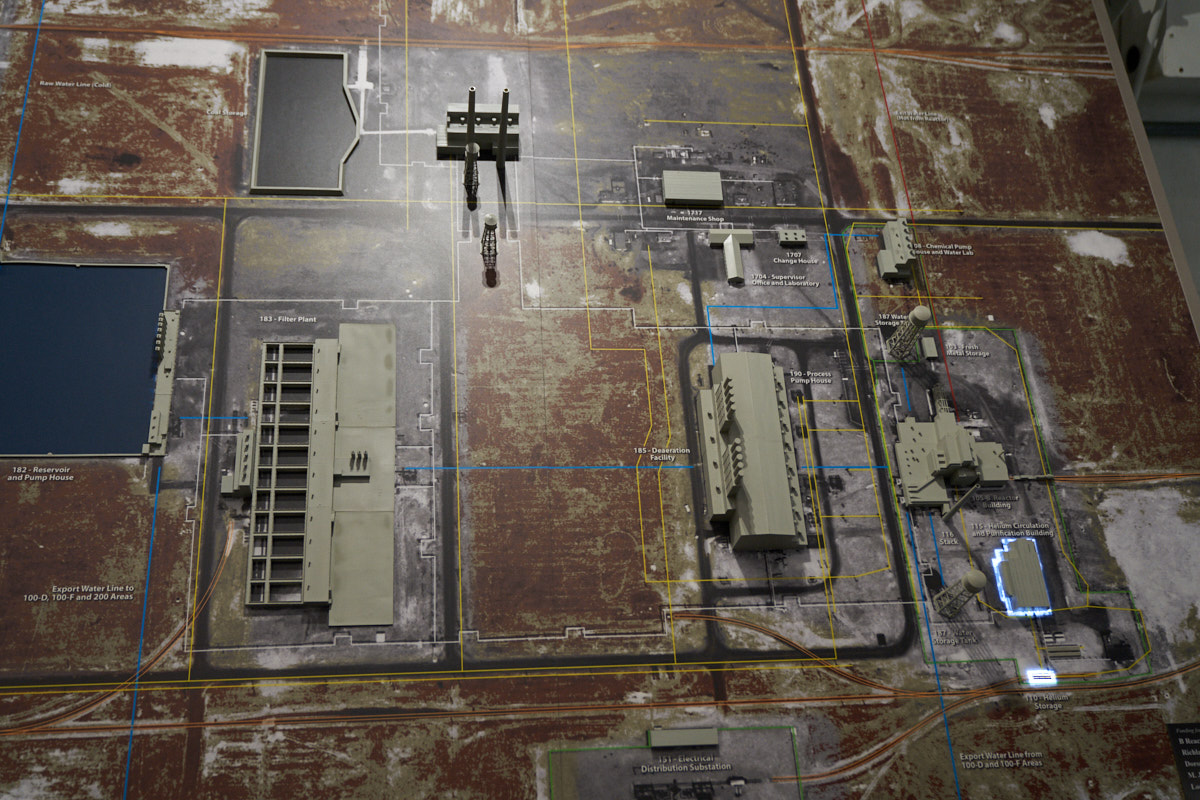

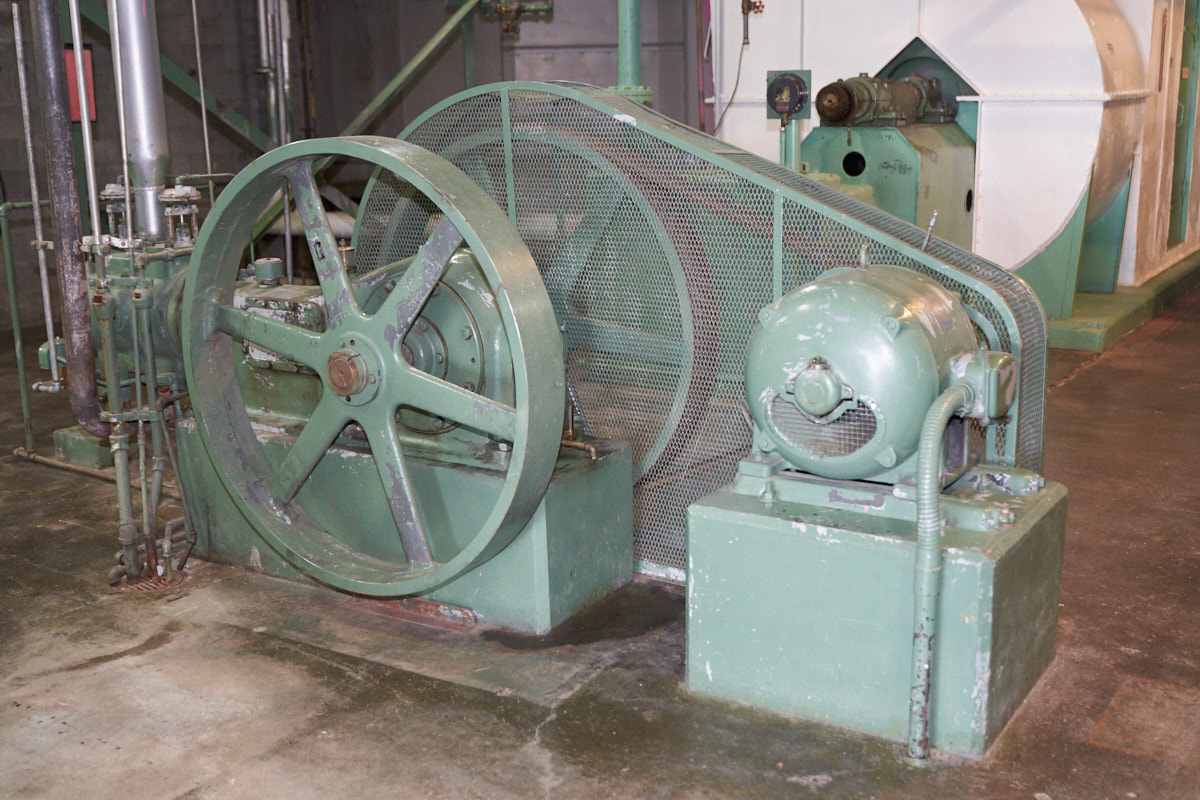

The B

Reactor itself was actually dwarfed by the support equipment

needed to operate it. Running a reactor like this was all

about keeping it cool and keeping the reactor cool required huge

amounts of ultra-clean water. Clean water was needed for a

variety of reasons including preventing unwanted absorption of

process neutrons and creation of radioactive byproducts.

The bulk of the facility was water treatment for the reactor.

The tour

took us over the valve pit that was used to control the influx

of purified, de-mineralized, de-aeriated water. The caps

on the valves were removed to show that the plumbing is not

being used which was a requirement of on-site inspections as

part of one of the nuclear treaties signed with the Soviet Union

during the cold war.

A sound

that you never want to hear.

One of

the safety features included in the design of the reactor plant

was high flow ventilation fans to remove contamination from the

air. These fans were powered by both steam and electric

motors to provide some redundancy.

A

close-up of some of the complex plumbing.

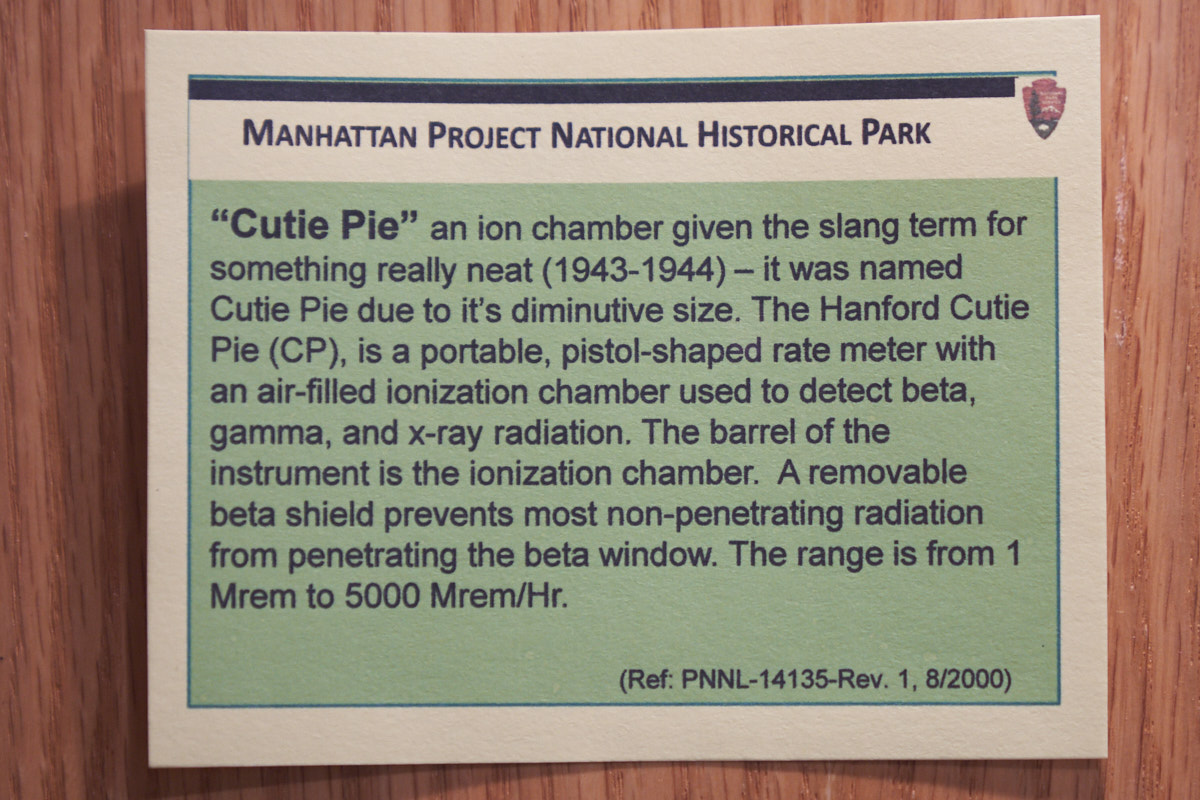

Early in

the development of atomic energy there arose a need to determine

the strength of radiation fields. The strength of these

fields determined the exposure that humans would suffer in the

presence of radioactivity. Instruments were developed to

detect and quantify the danger.

A

display of some of the radiation detection devices that were

employed at the Hanford site. The cutie pie is at the

upper left of the photo above.

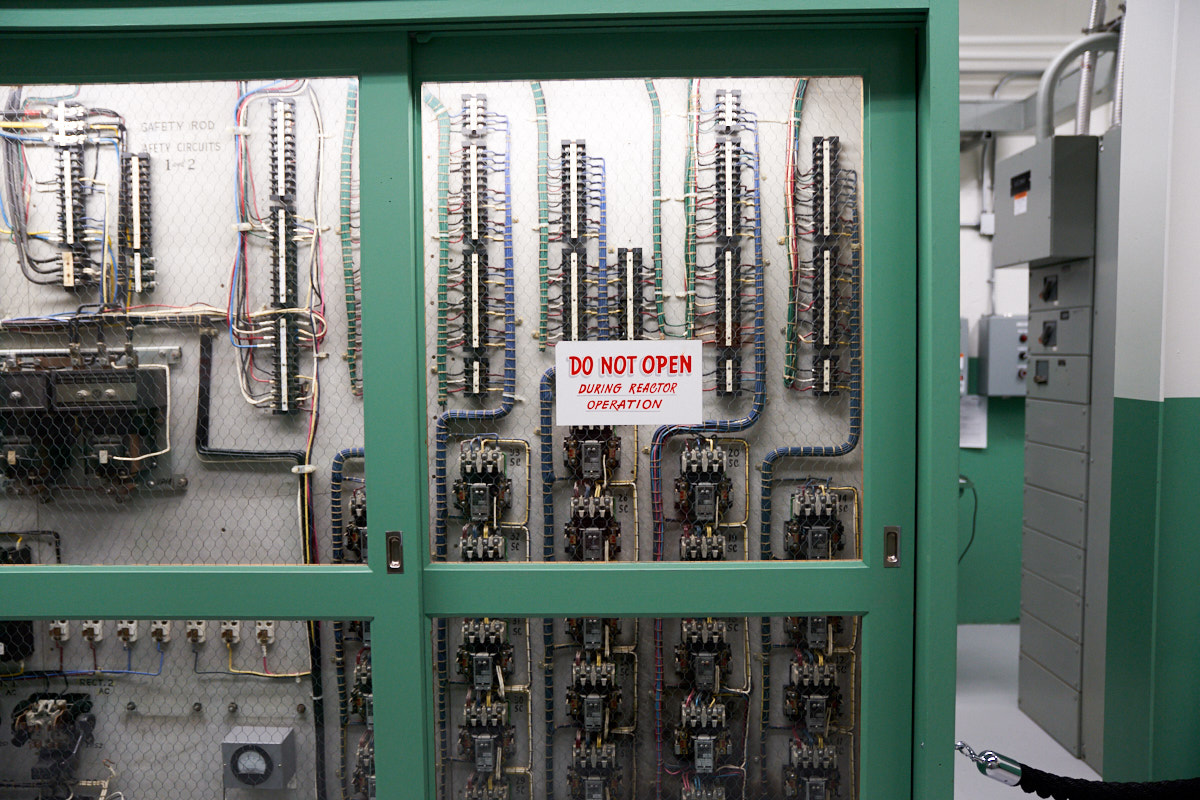

Signs,

signs, everywhere are signs.

One of

the displays showed the masks used as part of the PPE (personal

protection equipment) of the era.

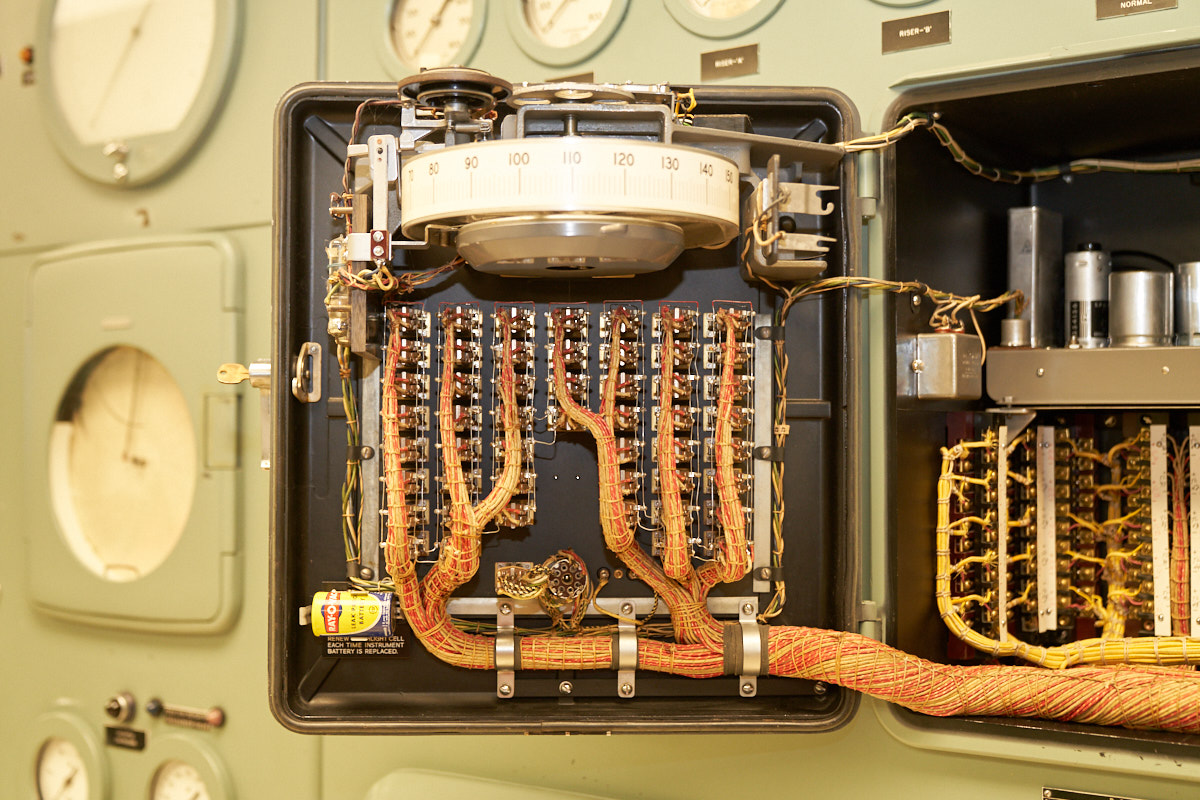

The tour

included a visit to the reactor control room. Obviously,

the original control room did not include video displays.

Back in

the day, it was all about analog dials and strip chart

recorders.

While not clearly

visible in the photo above, each of the strip chart recorders

had the word "unclassified" on each display. That would

lead me to believe that any display that was not marked

"unclassified" was, in fact, classified as it would allow a

knowledgeable person to deduce the plutonium production rate.

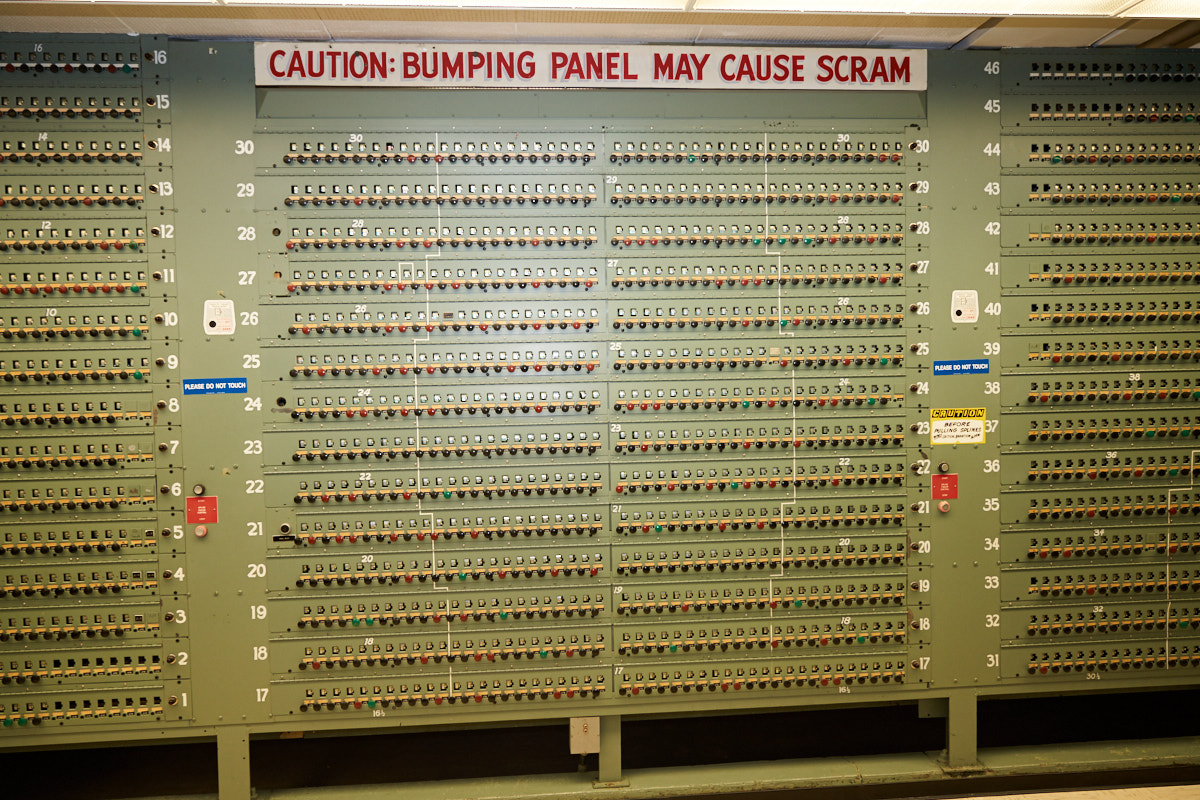

SCRAM is the term

used to describe an emergency shutdown of the reactor.

Each of the white squares above is a pressure display for the

associated end cap. These pressure readings would allow

determination of the operating status of each process tube.

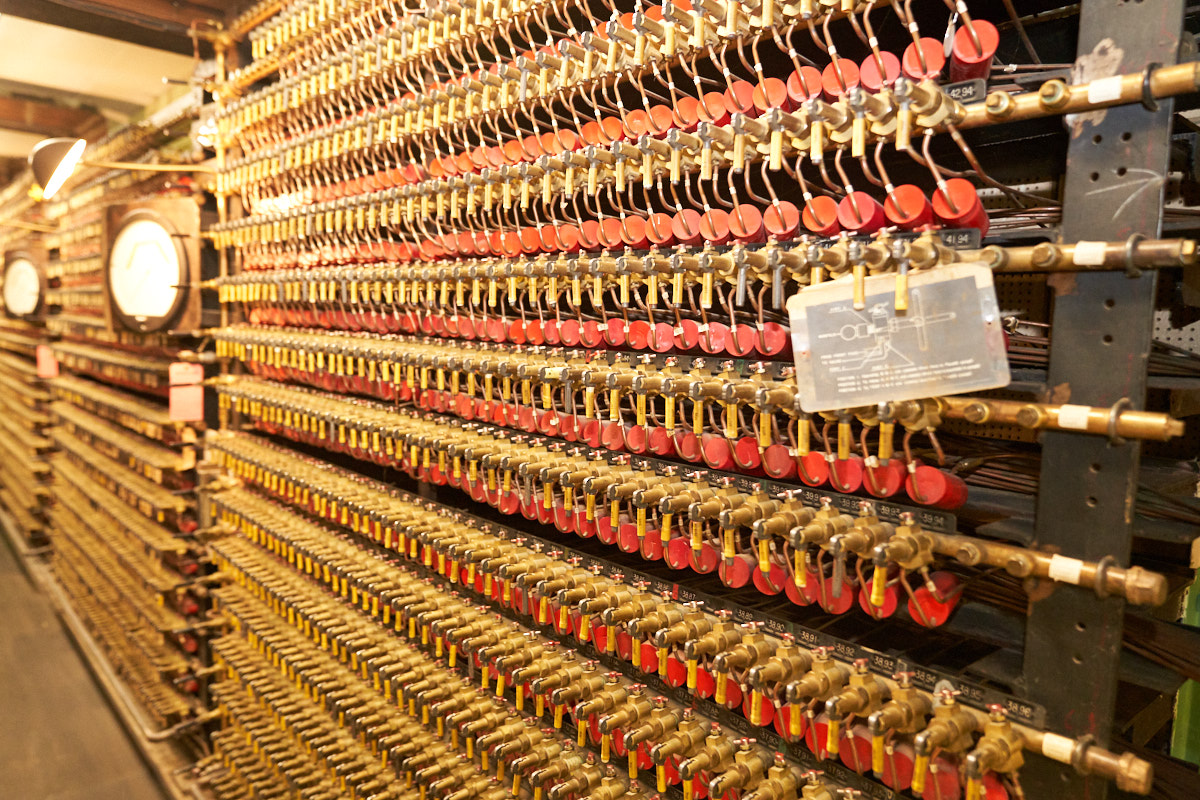

The rear portion of

the display board was a huge matrix of piping.

On the other side of

the aisle was additional plumbing with micro-valves to route

the pressure information to the display board.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2019, all rights

reserved.

For your enjoyment only, not for commercial use.