We were

moving quickly toward completion of the mounting of the Lance

1685 on Thor.

The photos below are what we saw.

The

final welds were performed to make the attachment of the Lance

to the sub-frame cross members permanent.

The

generator was mounted and a locking tab was welded on to deter

theft of the generator when parked.

The rear

tool box was re-attached. Once the rear tool boxes were

attached, we headed to fill the propane tank as we would

continue to live in Lance until the completion of the build-out.

The

preliminary test drive went well and we returned to the shop to

continue the build.

The

lower step on the Lance was removed and our stair mount was

added. The retracting stairs were deployed and the hand

rail added for security.

The

propane tank that we chose required the attachment of a remote

fill/vent device to allow filling the tank without getting

underneath the truck.

Some

cast-off seats were inspected for possible replacement of our

30-year-old stock seats.

The old

seats were removed in preparation for mounting.

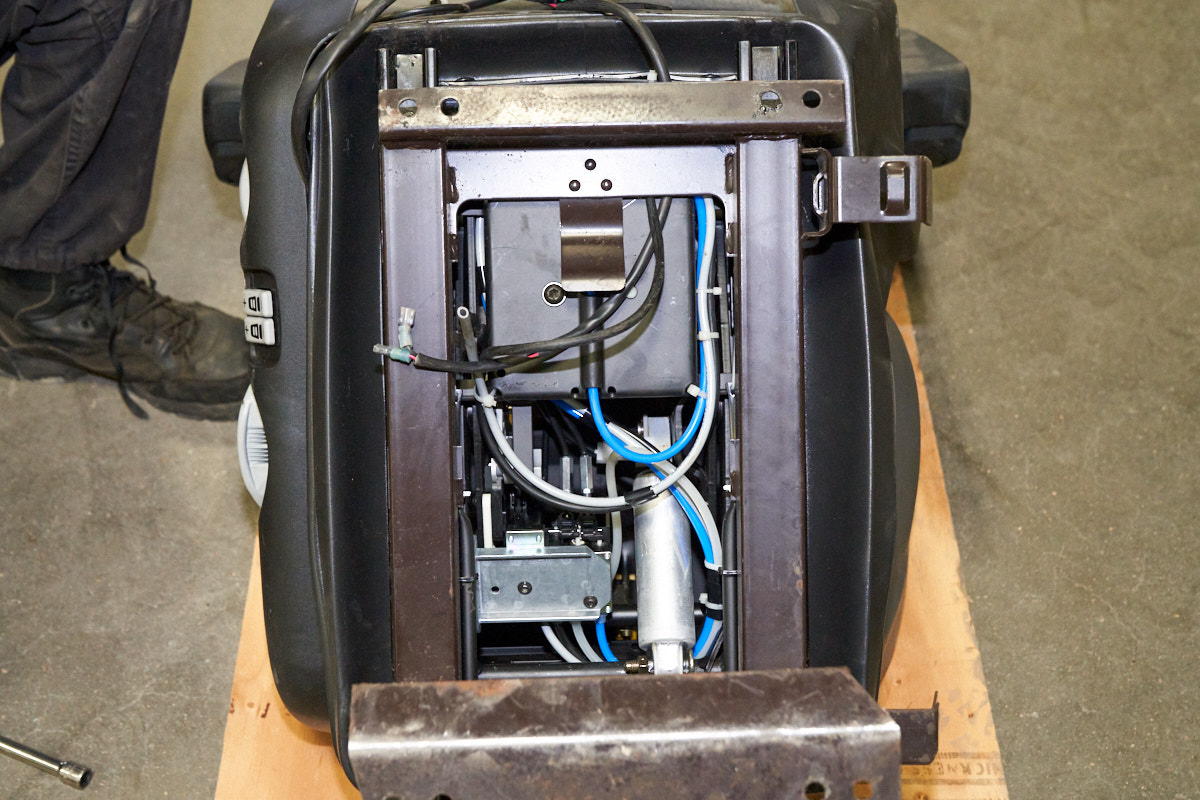

The

new-to-me seats require both 24v power and an air supply to

inflate the rubber bolsters and lumbar support bladders.

Our

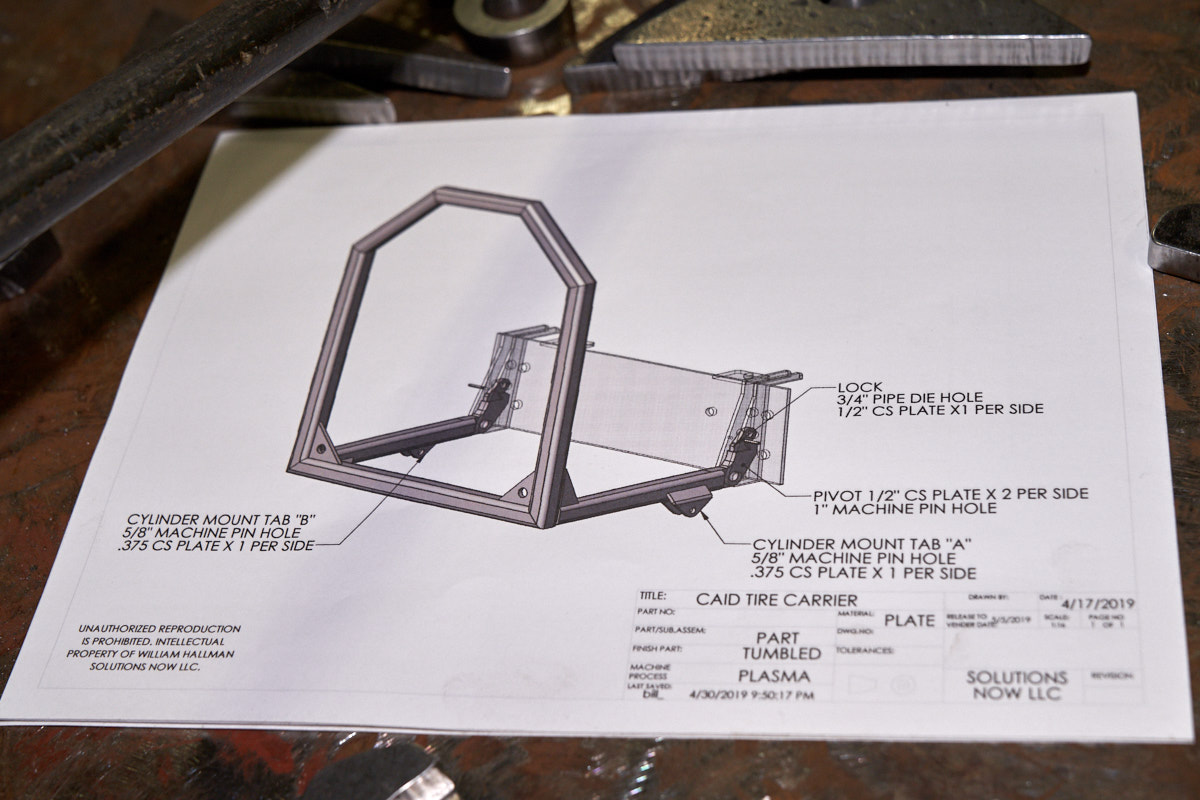

Solidworks-designed parts arrived from the machine shop.

A view

of the Solidworks design.

An

interesting aspect of this design is the locking pawls to

prevent the hydraulic system from being under load when the

truck hits a bump. The top bar will be manually rotated

counter-clockwise with a handle to unlock the mount. Once

the pawl is rotated clear, the hydraulic system can lower the

mount.

A "dirty

basket" was fabricated. The basket will allow storage of

dirty items on the frame of the truck behind the intercooler

rack.

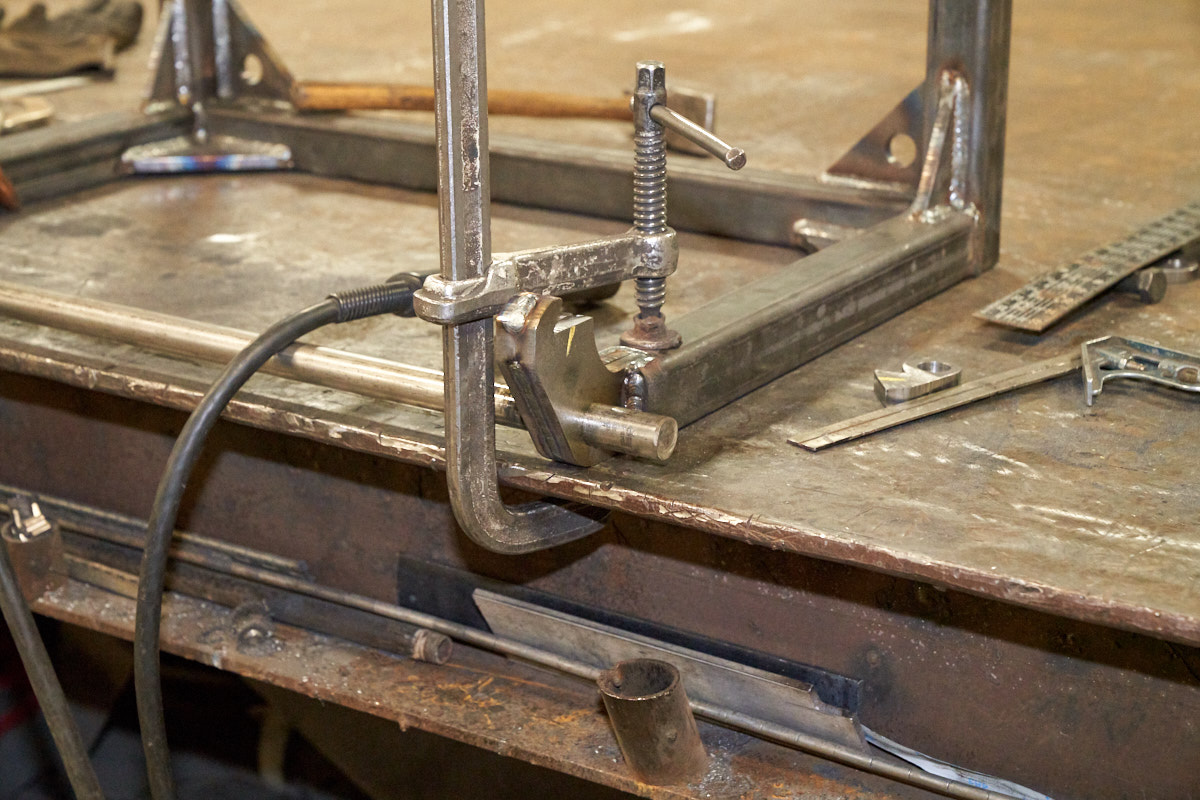

Using

the Solidworks drawings, the raw material for the tire handler

was cut to length.

A

test-assembly that shows how the components will mate.

The tire

frame approaches completion.

Test-fit

of the frame on an actual 395/85R20 tire.

Attending

to the details of the pawl/lock pivot interface.

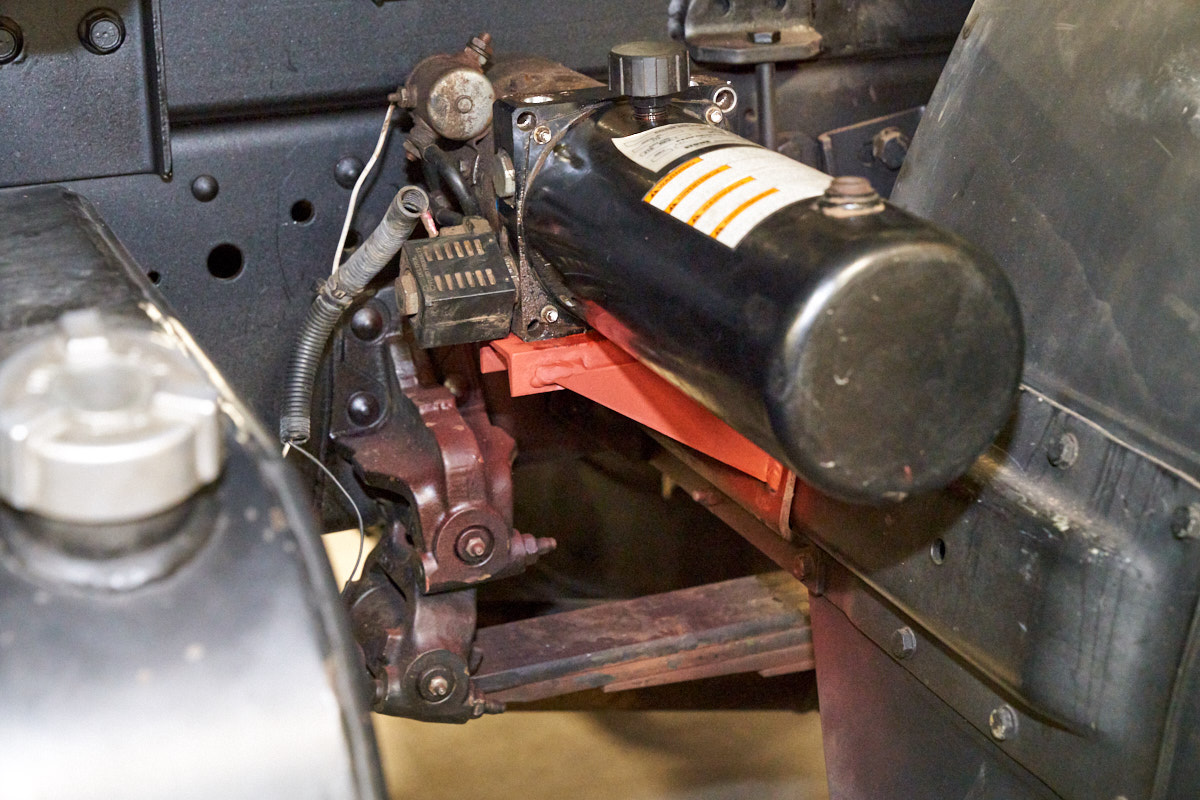

Hydraulic

mounting tabs were fabricated. These mounts were salvaged

from Thor's bash plate mount.

The

center portion of the front bumper was removed to reveal the

frame cross-members.

The tire mount was augmented with the locking pivot points.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2019 all rights

reserved.

For your enjoyment only, not for commercial use.