We made good progress in

the first 3 days of our effort. As our comfort level with the

specific actions improved, the rate of progress increased. During

the next 2 days, the sub-frame members were fabricated and a test

fitting of the camper on the truck frame was achieved. All of the

photos below were shot with my little Lumix camera which is 4 years

old, so the photo quality is somewhat lacking on some of the shots.

The photos below are what we saw.

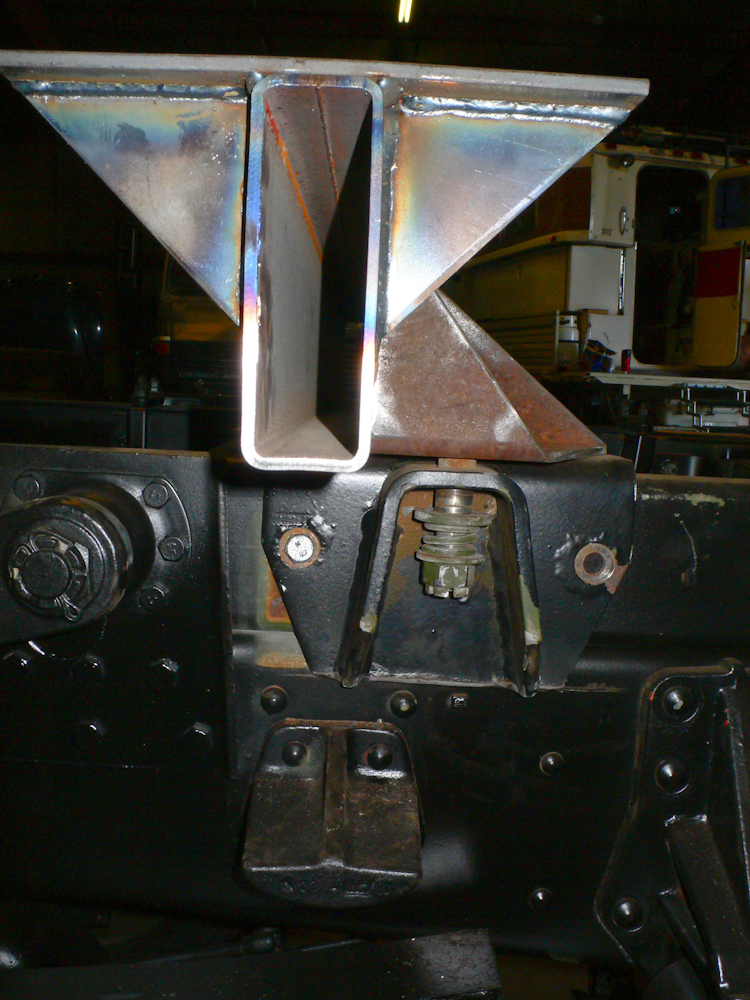

The fixed cross member

was the first beam constructed. We used 2 x 6 x 1/4" steel tubing

for the frame. A chunk of 6x6 was cut up to create the mounting

bracket. We elected to use the stock frame mounting bracket for

connection to the truck frame. But, to do so, we had to trim the

original bracket to make it clear some rivets in the frame and we had

to move it rearward several inches.

An end view of the

mounting bracket.

The bolt, castle nut and

spring washers were from the stock installation. A new hole will have

to be drilled through the frame member to allow full attachment of the

bracket to the frame in the new location.

Above is the rear mounting beam. This beam has cut-outs to provide clearance for the plumbing underneath the cabin. Sorry about the high-ISO speckle in the photo, but the flash did not fire.

Rob salvaged a mounting

assembly from a radio box that he had sitting around. The

assembly was the donor for the rubber grommet mounting eyes.

The mounting eyes were

cut from the existing frame using a plasma torch and then ground to

provide a clean, smooth surface for welding. An appropriate-sized

recess was then cut into the mounting beam and the eye was welded to

it. The welding was done in slowly in small increments to insure

that the rubber grommet was not melted due to the high heat generated

by the welding process.

The tire frame rack

mounts were welded to the cross member. The final, full "sew-up"

of all the welds will happen later.

The rear cross member of

the sub-frame was positioned under the camper for a test fit.

There were some straps that supported the gray water tank that had to

be cut and repositioned for the frame member to fit correctly.

All the junk under the

trailer was removed in anticipation of driving the 1017 under the

trailer. Note the clamps holding the rear frame member in place

at the far right of the photo above.

Two fork lifts were

required to lift the trailer. The plan was to get the lifts under

the center of gravity of the trailer, pick it up, and then drive the

1017 under it in the correct location. Then, using the side shift

feature of the fork lifts, the trailer would be set down on the 1017

frame in the correct location for the test fit. Due to the tight

space, positioning the first lift was a bit challenging, but the short

wheelbase won in the end. Note the U500 (for sale) in the

background.

Rob positions the second

fork lift into place.

We have lift-off.

Driving very slowly, with

much spotting, I backed the 1017 under the suspended trailer.

We slowly lowered the

trailer onto the 1017 frame.

We had a small

"situation" with the forks on the passenger side. In the end, we

put some blocks on top of the cross frame and lowered the trailer onto

them. Then, the forks were repositioned, the trailer was raised

and the blocks removed.

The full weight of the

trailer is on the 1017 frame. Because we disconnected the

electrical setup for the hydraulics, we were unable to lower the top

before picking up the trailer. But, in the end it did not matter;

the weight distribution of the trailer was favorable and it was not an

issue. The trailer sits quite high on the truck; note the height

of the trailer relative to Kathleen (who is about 5'8"). Also

note that the trailer is not sufficiently heavy to cause the frame of

the 1017 to sit level.

A photo taken from the

tailgate of the 1300 shows a different view of the setup.

While it is a poor photo

due to insufficient light and a weak flash, the photo above does show

the height of the camper when the top is raised. Our measurements

suggest that the top is about 13.5' when raised. The camper does

not appear to be sitting plumb, but that is an artifact of the angle of

the photograph.

A rear view of the pivot

position with the scrap mount in place for example. The mount

will we re-fabricated with thicker material and then welded to the

cross member.

| Previous Adventure | ||

| Trip Home Page |

Photos

and Text Copyright Bill Caid 2010, all rights reserved.

For your enjoyment only, not for commercial use.